Incoloy Pipe Fittings Supplier & Exporter in Singapore — Precision Engineered for Critical Industries

Introduction: Building Resilient and High-Performance Piping Systems in Singapore

In rapidly evolving industrial environments like Singapore, where precision, safety, and durability are essential, the choice of pipe fittings can make or break system performance. Industries such as oil and gas, petrochemical processing, marine engineering, power generation, semiconductor fabrication, and food & beverage production demand piping components that resist corrosion, withstand high temperatures, and maintain mechanical strength under constant stress.

That’s where Incoloy pipe fittings come into play. Manufactured from premium nickel-based alloys, Incoloy fittings exhibit outstanding corrosion resistance, excellent thermal stability, and superior mechanical properties — addressing the challenges of demanding industrial conditions. Mcneil Instruments , a reputed manufacturer, supplier, and exporter, supplies Incoloy pipe fittings engineered to international standards and optimized for Singapore’s industrial requirements.

In this blog, we’ll break down the features, specifications, materials, applications, and certifications that make Incoloy pipe fittings an ideal choice for Singaporean industries.

What Are Incoloy Pipe Fittings?

Incoloy pipe fittings are specialized components fabricated from high-performance nickel-iron-chromium alloys. These fittings connect, redirect, or terminate piping systems while ensuring leak-proof performance at high pressures and temperatures.

Incoloy alloys are engineered to perform in corrosive, oxidizing, and high-temperature environments, giving them a distinct advantage over standard carbon steel and many stainless steels. Their applications span industries that require long service life and minimal maintenance in challenging service conditions.

Incoloy Materials and Their Key Properties

Mcneil Instruments supplies Incoloy pipe fittings in multiple grades that address different industrial challenges. The most widely used Incoloy alloys for pipe fittings include:

Incoloy 800 Pipe Fittings

- Composition: Nickel-iron-chromium alloy with moderate chromium content.

- Strengths: Excellent resistance to oxidation and carburization in high-temperature environments.

- Applications in Singapore: Heat exchangers, furnace piping, refinery regenerators, steam systems.

Incoloy 800H Pipe Fittings

- Composition: Thermally stabilized variant of Incoloy 800.

- Strengths: Superior creep resistance and tensile strength at elevated temperatures.

- Applications in Singapore: High-temperature process lines, thermal processing equipment.

Incoloy 825 Pipe Fittings

- Composition: Nickel-iron-chromium alloy fortified with molybdenum and copper.

- Strengths: Exceptional resistance to reducing acids, pitting, and crevice corrosion.

- Applications in Singapore: Chemical processing plants, sour gas environments, offshore installations.

Incoloy 925 Pipe Fittings

- Composition: A high-strength alloy combining Nickel, Chromium, Molybdenum, and Copper.

- Strengths: Outstanding resistance to stress corrosion cracking, high mechanical strength under load.

- Applications in Singapore: Marine engineering, drilling platforms, high-pressure piping systems.

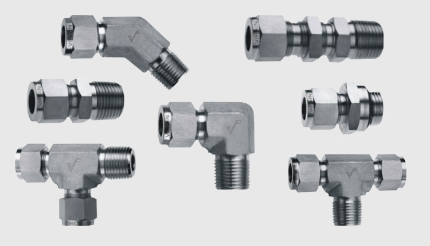

Types of Incoloy Pipe Fittings Available

Mcneil Instruments provides a wide range of Incoloy pipe fittings to meet diverse industrial needs:

- Elbows (45°, 90°, 180°): For directional changes in piping runs.

- Tees & Crosses: For branching connections.

- Reducers (Concentric & Eccentric): For transitions between pipe sizes.

- Caps & Plugs: To close off pipe ends securely.

- Adapters & Couplings: For joining dissimilar pipe types or sizes.

- Stub Ends & Flange Adaptors: For welding and flange assembly systems.

- Custom Machined Fittings: Tailored solutions for specific applications.

Each fitting is precisely machined and tested to ensure a secure, leak-resistant joint.

Standards, Specifications & Compliance for Singapore Projects

Incoloy pipe fittings supplied by Mcneil Instruments adhere to internationally recognized standards, ensuring compatibility with global piping systems deployed in Singapore:

| Standard | Description |

| ASTM B366 | Standard specification for Incoloy fittings |

| ASME SB366 | ASME designation for nickel alloy pipe fittings |

| ISO / API Standards | Applicable as per project or industry requirements |

| ASME B16.11 | Forged fittings, socket weld & threaded fittings |

| ASME B16.9 | Factory-made wrought butt weld fittings |

These standards ensure that the fittings are produced with consistent metallurgy, mechanical performance, and dimensional accuracy suitable for industrial service.

Technical Specifications of Incoloy Pipe Fittings

| Specification | Details |

| Material Grades | Incoloy 800, 800H, 825, 925 |

| End Connections | Butt Weld, Socket Weld, Threaded |

| Size Range | 1/8″ NB to 24″ NB (custom sizes available) |

| Pressure Class | Up to 6000 psi |

| Temperature Range | –196°C to +982°C (depending on alloy) |

| Test & Inspection | Hydrostatic, Pneumatic, NDT (Ultrasonic / Radiographic), PMI |

| Certifications | EN 10204 3.1/3.2 Material Test Certificates |

These specifications ensure that the fittings perform reliably in high-temperature, corrosive, and high-pressure systems often found in Singapore’s industrial sector.

Why Incoloy Pipe Fittings Are Suited for Singapore’s Industrial Sector

Corrosion Resistance in Aggressive Environments

Singapore’s chemical processing and marine industries expose pipe systems to corrosive and chlorinated environments. Incoloy alloys resist pitting, crevice corrosion, and stress corrosion cracking — outperforming many stainless steel grades in such conditions.

Outstanding Thermal Performance

In applications such as petrochemical heaters, furnaces, and heat exchangers, Incoloy fittings maintain mechanical integrity at temperatures where other alloys might weaken or deform.

Strength and Durability

Incoloy alloys exhibit high tensile strength and toughness, ensuring long service life even under cyclic load and thermal stress.

Compatibility with Diverse Media

Whether gases, steam, acids, or saline water, Incoloy pipe fittings handle a wide spectrum of media with reduced risk of corrosion or material attack.

Applications Across Singaporean Industries

Incoloy pipe fittings find extensive use in Singapore’s industrial landscape:

Oil & Gas and Petrochemical Plants

Used in process lines, sour gas environments, and high-temperature feed systems.

Power Generation Facilities

Steam and fluid handling in turbines, boilers, and auxiliary utility systems.

Marine Engineering

Piping systems on ships, offshore platforms, and coastal installations where chloride exposure is significant.

Chemical Processing

Corrosive media conveyance, chemical dosing systems, and reactor feed lines.

Semiconductor and Electronics Manufacturing

Ultra-clean, high-temperature systems require corrosion-resistant alloys to maintain quality standards.

Food & Beverage and Pharmaceutical

Sanitary and corrosion-resistant systems for processing and utilities.

Quality Assurance, Inspection & Testing

Mcneil Instruments ensures that every Incoloy pipe fitting meets or exceeds quality expectations through rigorous procedures:

- Material Certification (EN 10204 3.1/3.2)

- Positive Material Identification (PMI)

- Chemical and Mechanical Testing

- Hydrostatic and Pneumatic Pressure Testing

- Non-Destructive Examinations (Ultrasonic / Radiographic)

- Dimensional and Visual Inspection

These steps guarantee compliance with project specifications and ensure that the fittings perform reliably in operation.

Why Choose Mcneil Instruments — Manufacturer, Supplier, and Exporter

Comprehensive Material Expertise

Mcneil Instruments ’s team understands material metallurgy, service conditions, and industry requirements — advising on the right Incoloy grade for specific applications.

ISO-Certified Manufacturing

Production facilities follow strict quality management systems backed by ISO 9001:2015 certification.

Global Supply Chain with Local Support

As an exporter with a worldwide logistics footprint, the company ensures delivery to Singapore’s project sites with full documentation support.

Custom Engineering Solutions

Beyond standard offerings, Mcneil Instruments provides tailor-made fittings that meet unique project specifications.

End-to-End Traceability

From raw material batch to final inspection, every Incoloy fitting is fully traceable — critical for audit and compliance requirements.

Conclusion: High-Performance Fittings for Singapore’s Industrial Growth

Incoloy pipe fittings are engineered components that deliver exceptional corrosion resistance, high-temperature performance, and mechanical strength — qualities essential for Singapore’s industrial infrastructure.

Whether deployed in marine, offshore, petrochemical, power generation, or precision manufacturing sectors, these fittings ensure stable, long-lasting performance when standards and safety cannot be compromised.

As a trusted manufacturer, supplier, and exporter, Mcneil Instruments provides globally certified Incoloy pipe fittings that meet Singapore’s rigorous industrial demands — empowering engineers and procurement teams with quality, reliability, and peace of mind.