Best 2 Valve Manifold Valve Manufacturers in India

Manifold Valves Manufacturer Suppliers, Exporters in India

Mcneil Instrument, a trusted name in the industry, is among the leading manifold valve manufacturers in India. With a commitment to quality and precision engineering, Mcneil Instrument designs and produces a wide range of manifold valves suitable for various industrial applications. These manifold valves serve as critical components in controlling the flow of liquids and gases in pipelines and systems, ensuring efficient and safe operations.

As reputable manifold valve suppliers in India, Mcneil Instrument caters to diverse customer requirements with its comprehensive product range. Whether it’s for oil and gas, chemical processing, power generation, or any other industry, Mcneil Instrument offers reliable solutions tailored to meet specific needs. Their manifold valves are known for their durability, performance, and adherence to international standards, making them a preferred choice for discerning clients nationwide.

What is a Manifold Valve?

A manifold valve combines multiple valves into one system, acting as a bridge between instrumentation and processes. Manifold Valves offer two main benefits over individual valve installations:

- Cost Efficiency: Reduces space and potential leak points compared to multiple individual valves.

- Convenient Configuration: Allows calibration or replacement of measuring instruments without plant shutdown, improving efficiency and safety.

Manifold Valves Manufacturer and Supplier in India

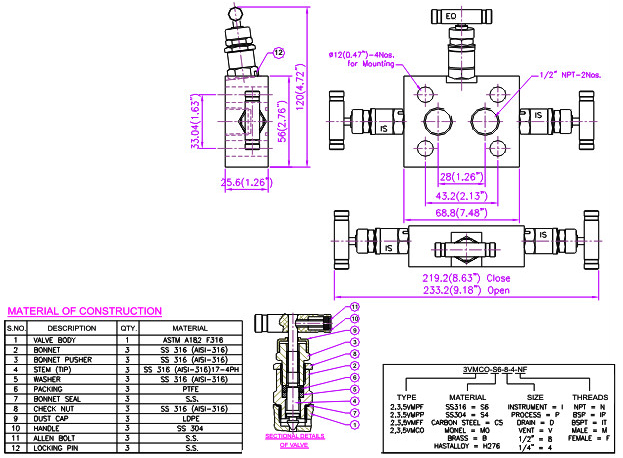

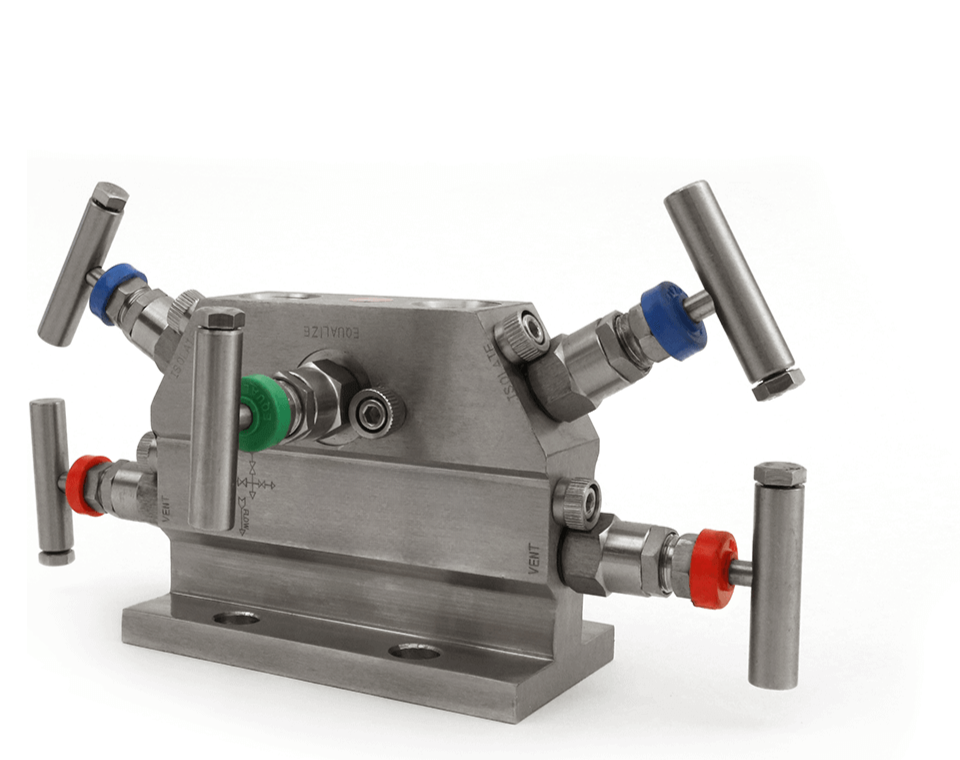

Mcneil Instruments offers manifolds designed for direct installation on transmitters featuring 54 mm or 32 mm center-to-center connections. The inlet options include either ½” wide “Flanged or NPT F connections. Each manifold comes equipped with two isolation valves, one equalizer valve, and 1/4” tubing. Alternatively, an NPT F drain can be utilized. These valves are primarily intended for Dp transmitters, serving as a common application. Mcneil Instruments ensures that its manifold valves meet international quality standards, crafted from high-grade raw materials. Additionally, custom-designed manifold valves are available to tailor to the specific requirements of customers.

Manifold Valve Manufacturers in India, Manifold Valve Exporters, Manifold Valve Suppliers in India, Manifold Valve Manufacturers, Manifold Valve Exporters in India, Manifold Valve in India, Manifold Valve Suppliers, Manifold Valve

Mcneil Instruments Inc offers a variety of instrument manifolds valves, including 2 Valve manifolds designed for static pressure and liquid level applications. These manifolds are available in traditional and compact body designs. Manifold connections include female tube fittings, pipe ends (NPT and ISO 228/1), and flanges (MSS SP-99) in 1/2 and 3/4 in. and 12 mm sizes.

We are the trusted name in the industry for manufacturing and supplying manifold valve for pressure gauge, valves, fittings, and industrial couplings with adapters. We serve a wide range of industrial sectors, providing products that conform to industry standards and ensure safety and system efficiency with their precision design.

Products

Uses and Advantages of Manifold Valves

| Uses of Manifolds Valve | Advantages of Manifolds Valve |

| Blocking a connection to the process | Reduced leakage risk with fewer joints and connections |

| Equalizing pressure between measuring ports | Lower installation costs due to compact design |

| Bleeding the segment between instrument and process | Complete pressure-tested assembly ensures reliability |

| Ideal for industries: oil & gas, petrochemical, chemical, power generation, water treatment | Shorter flow path minimizes pressure drop and heat loss, boosting efficiency |

| Versatile designs for various installation types: instrument, remote-mount, and direct-mount systems | |

| Compact size enables use in confined spaces | |

| Simplified operations and improved layout with fewer hoses and connections | |

| Enhanced reliability and operator safety |

Type 2VR / U2VR

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

In gauge and static instrument applications, such as pressure switches, pressure transmitters, and manometers, the 2-valve isolating and venting manifold is typically employed.

Type 2VG / U2VG

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

The ‘2VG’ Series 2 valve gauge manifold provides regulated venting and single process isolation. There are male inlet and female outlet connections available for the “2VG” Series.

Type 2VBD

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

Use pressure transmitters with the 2-valve direct mount manifold. The manifold will separate the instrumentation from the process and enable venting for calibration or removal from the circuit without impairing the process, application, recovery of a sample, etc.

Types of Three-Way Manifold Valves

Type 3VR

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

Use pressure transmitters with the 2-valve direct mount manifold. The manifold will separate the instrumentation from the process and enable venting for calibration or removal from the circuit without impairing the process, application, recovery of a sample, etc.

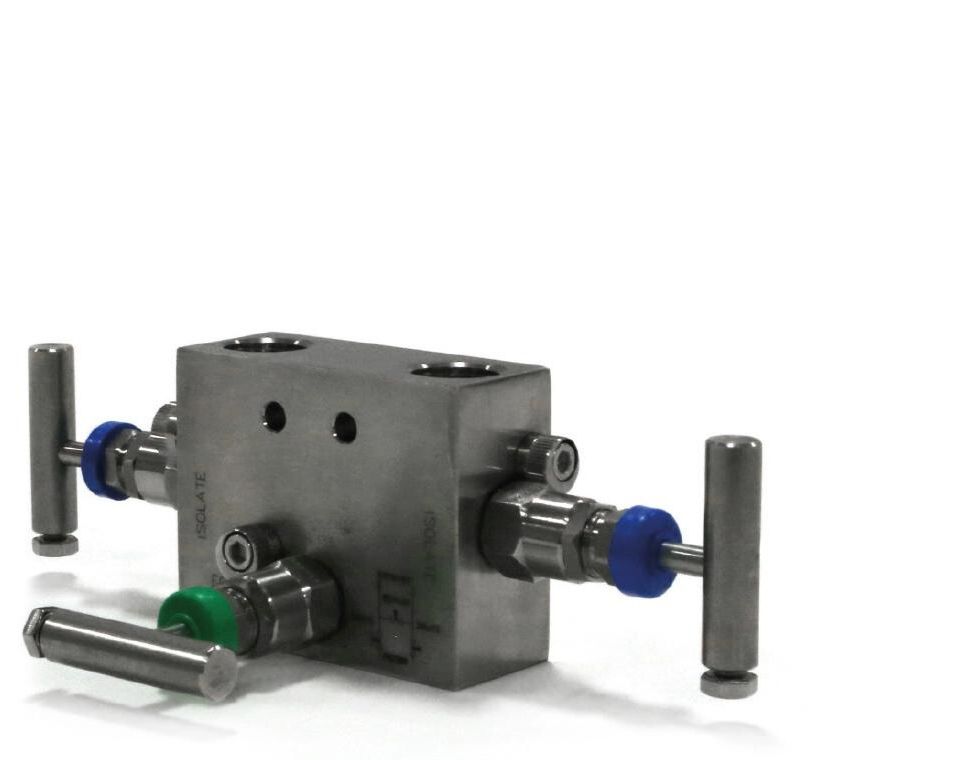

Type 3VBD

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

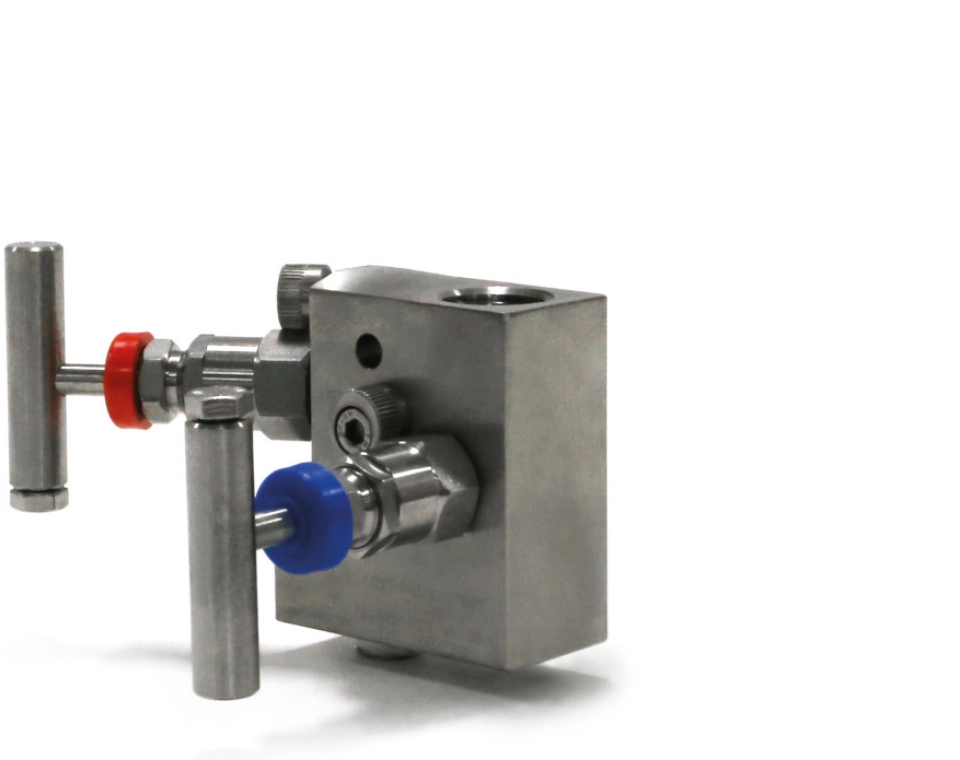

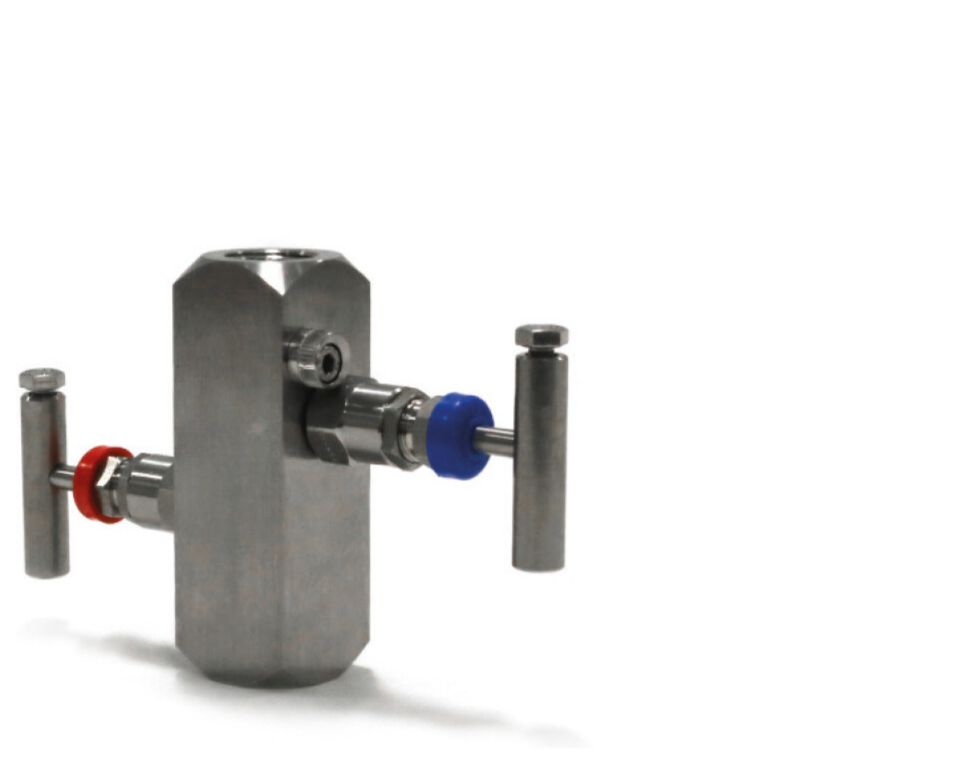

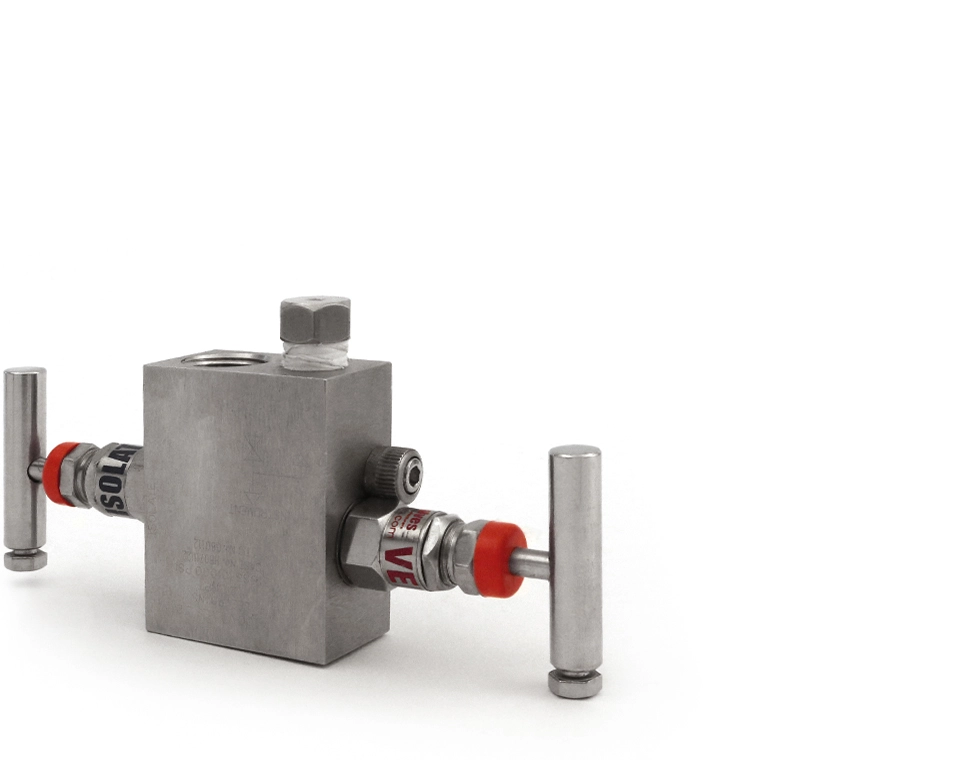

3-valve direct mount manifold with pipe connection from instrument mount. offers two isolation valves and one equalizing valve for use with static instruments or differential pressure transmitters.

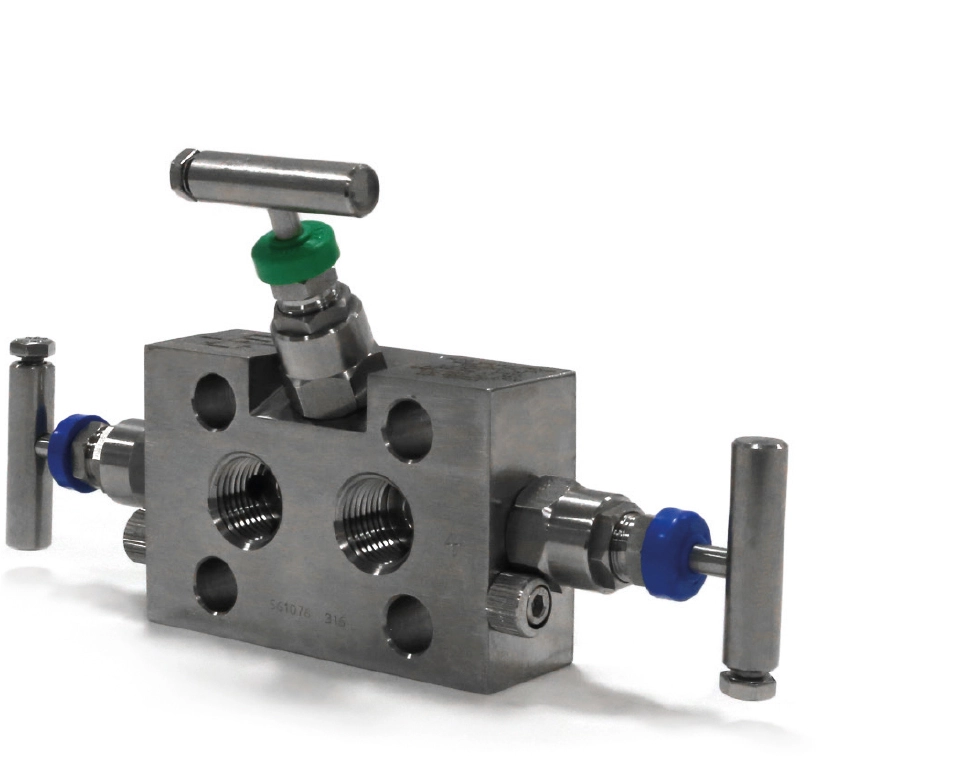

Type 3VD

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

3-valve manifold with direct mount, pipe connection to instrument mount. Its ‘T’ section body provides a suitable space envelope between the process lines and the instrument. One equalizing valve and two isolation valves are available in the “3VD” Series.

Types of Five-Way Manifold Valves

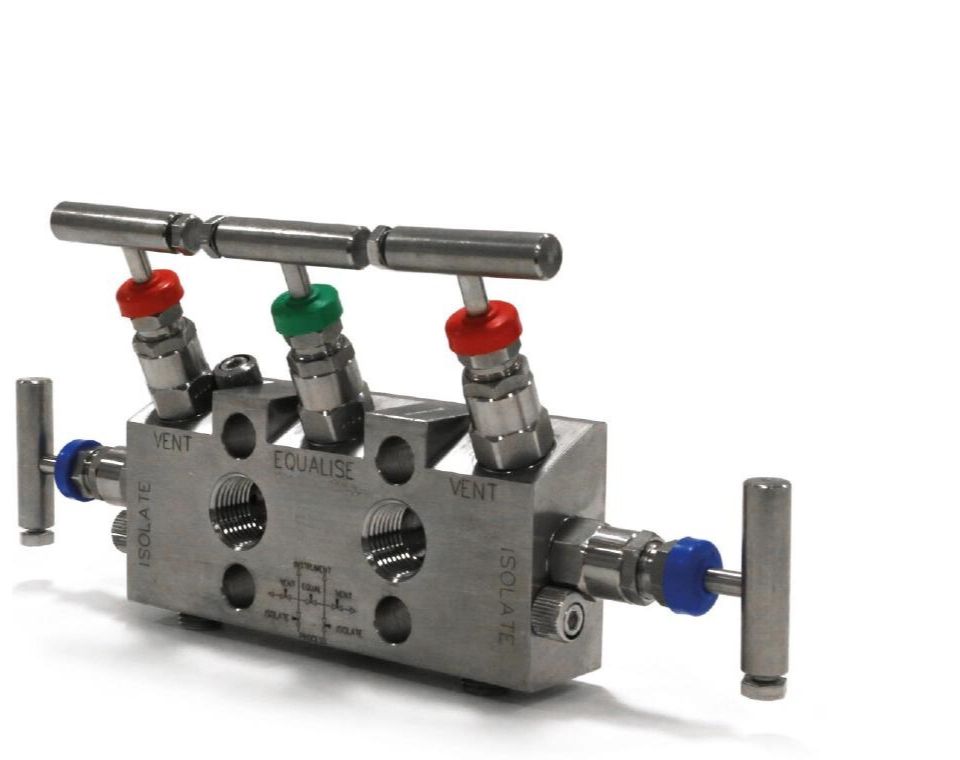

Type 5VR

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

Pipe to pipe, remote-mounted, five-valve manifold. offering two isolation valves, two vent valves, and one equalizing valve in an oil variant. used in static instrument applications and differential pressure transmitters.

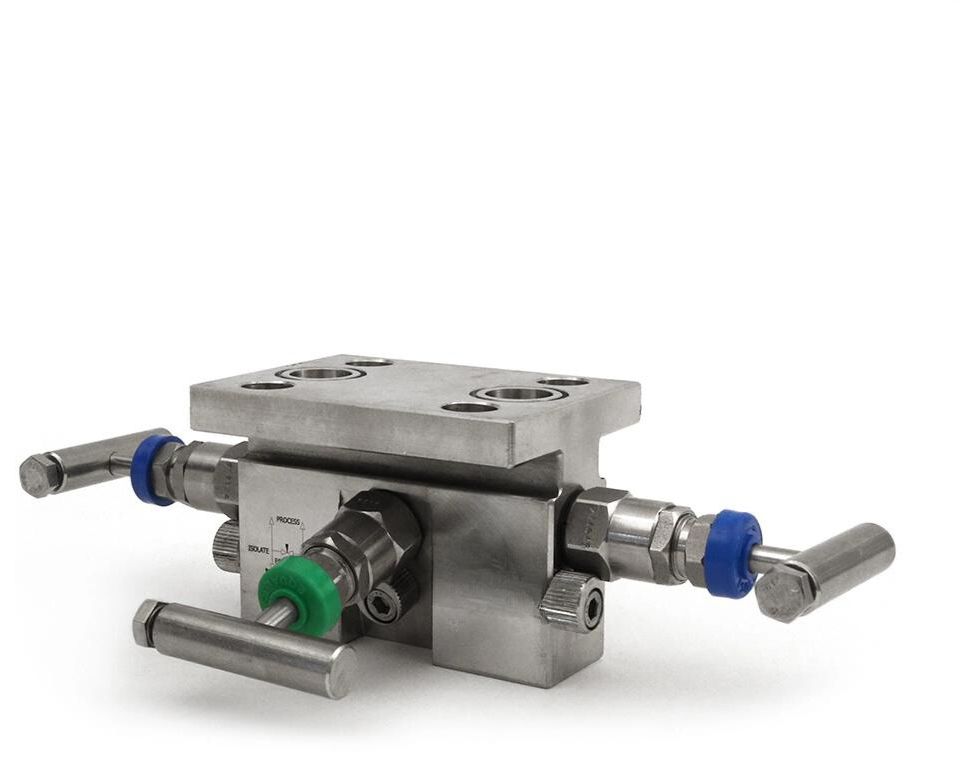

Type 5VBD

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

5-valve manifold mounted directly to a block with an instrument mount to pipe connection. offering two isolation valves, two vent valves, and one equalizing valve in an oil variant. used in static instrument applications and differential pressure transmitters.

Type 5VD

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

5-valve direct-mount manifold with pipe connection from instrument mount. offering two isolation valves, two vent valves, and one equalizing valve in an oil variant. A ‘T’ section body format enables a sufficient distance between the instrument and process lines.

2 Way Manifold Valve | 3 Way Manifold Valve | 5 Way Manifold Valve

The applications of manifold valves made in India include for differential pressure, liquid level, and static pressure. They are simple to install and maintain, and they have less possible leaks. Manifold valves are offered in three distinct configurations: two-way, three-way, and five-way. The compact assembly design of the Manifold Check Valve accounts for its decreased weight and size. Manifold valves have the following qualities: long life service, ease of operation, and leak resistance.

How Manifold Valve Function

A manifold valve for a pressure gauge is a device used to control the flow of fluids in a system, specifically for managing pressure readings. Instrument manifold valves combine multiple valves into a single unit, allowing precise control over the flow paths connected to a pressure gauge.

The main functions of a manifold valve for a pressure gauge include:

- Controlling Flow: It regulates the fluid flow to the pressure gauge, ensuring accurate pressure readings.

- Isolating the Gauge: Instrument manifold valves can shut off flow to the pressure gauge during maintenance or calibration without affecting the entire system.

- Equalizing Pressure: It helps balance pressure within the system to protect the pressure gauge and other instruments from potential damage.

In essence, using a manifold valve with a pressure gauge enhances the efficiency and safety of monitoring pressure in industrial systems.

Best Manifold Valve Manufacturers in India

The Manifold Valve Manufacturer in India. joins two or more hydraulic system valves. These valves are employed in a wide range of applications, from heavy industrial instruments to mobile machines. Manifold Valves showcased lower costs and increased efficiency. These manifold valves include a range of end connections and can work at pressures up to 20,000 psi (1,379 bar). Manufacturers of premium metal manifold valves with ISO certification in India provide a wide range of sizes and weights.

Best Manifold Valve Suppliers in India

Mcneil Instruments inc. is a leading supplier of high-quality Manifold valves to our esteemed customers. The differential pressure transmitter is intended to be directly mounted to these valves. We are the biggest suppliers of manifold valves. Our whole inventory is stocked and available for prompt shipping to India, Gulf, Quwait, Saudi Arebia, Qatar, Oman, Gulf Countries, Nigeria, Dubai, Singapore, Philippines, Thailand, Vietnam to all petrochemical industries.

Best Manifold Valve Exporters in India

As manifold valve exporters in India, Mcneil Instrument extends its reach to global markets, providing good quality products to clients worldwide. Our dedication to excellence, coupled with competitive pricing and prompt delivery, has earned them a strong reputation as a trusted partner in the global marketplace. Mcneil Instruments Inc. Export Manifold Valves to Kazakhstan, Algiers, Johannesburg, Ghana, Uganda, Iraq, Subra al-Haymah, Australia, Yaounda, South Africa, Saudi Arabia, Ethiopa, Kuwait, Luanda, Abu Dhabi, Peru, Sudan, Colombia, Nairobi, Turkey, Russia, Khartoum, Kano, UAE, Bahrain, Cape Town, Trinidad and Tobago, Dar es Salaam, Nigeria, Antananarivo, Tripoli, Addis Ababa, London, Douala, Lebanon, Tunisia, Ouagadougou, Mogadishu, Harare, Mbuji-Mayi, Qatar, Zaria, Soweto, Omdurman, Angola, Alexandria, Dubai, Yemen, Casablanca, Africa, Oman, Giza, UK, Houston, Accra, Algeria, Argentina, Cairo, Chine, Kolwezi, Hong Kong, Abidjan, Vietnam, Port Elizabeth, Maputo, Canada, Port Harcourt, Singapore, Egypt, Venezuela, Freetown, Ibadan, Iran, Malaysia, Mexico, Cameroon, New York, Indonesia.

Specification of Manifold Valves

| Specification | Manifold Valves |

|---|---|

| Temperature of Media | Medium Temperature |

| Operation Way | Manual, Electric actuator, Pneumatic |

| Size Range | 1/8 to 1”, Custom Sizes available |

| Design | Integral Bonnet Design, Forged Body with Inline/Straight or Angle Pattern |

| Standard | 3A/ ISO/ DIN/ SMS / ASTM / JIS |

| Leakage rate |

|

| Working pressure | Up to 6000 PSIG

Manifold Valves are also available in higher pressure. |

| Seal ring material | PPL, PTFE, PPL Soft Graphite |

| Connection |

|

| Power | Manual |

| End Connection |

|

| Temperature Range |

|

| Manufacturer of various Thread Type |

|

| Manifold Valves Material (MOC) | SS 316, SS 304, C.S, F11, Duplex, Super Duplex, Hastelloy, Monel 400 |

| Function |

|

| Flow Rate | .93, 2.34, 6.42, .70, 1.04, 3.62,.87 Cv |

Whether you’re in search of top manifold valves manufactured to the highest standards, reliable suppliers in India, or exporters capable of meeting international demands, Mcneil Instrument stands out as a dependable choice, delivering superior quality products and unmatched service to meet your manifold valve needs.

People Search For

alloy steel manifold valves distributors, Manifold Valve Manufacturers, alloy steel manifold valves stockholder, alloy steel manifold valves price, alloy steel manifold valves manufacturer in Mumbai, cr-mo 5 valve remote mounted, alloy steel types of manifold valves, Manifold Valve Manufacturers in India, alloy steel 3 way manifold price list, chromium molybdenum 2 valve t type manifold valve, alloy steel manifold valves manufacturers in india, buy high quality alloy steel manifold valves, alloy steel manifold valves types, chromium molybdenum 2 way manifold valve for pressure gauge, Manifold Valve Exporters in India, alloy steel manifold hydraulic valves, Best Manifold Valve Exporters in India, alloy steel manifold 3 valves 2 ways, Best Manifold Valve Manufacturers in India, cr-mo manifold mounted ball valves, alloy steel manifold valves stockists, alloy steel manifold valve size, Manifold Valve Suppliers in India, crmo 3 valve direct mounted, chrome moly manifold valve application, crmo manifold valve dealers, alloy steel manifold valves traders, Best Manifold Valve Suppliers in India.

Material Testing Procedures

We conduct a range of material tests to validate valve durability and performance, including:

| Test Type | Description |

| Burst Test | Tests for rupture resistance under pressure |

| Ultrasonic Test | Detects internal flaws within the material |

| Mechanical Testing | Assesses the mechanical strength of the valve |

| Cryogenic Testing | Validates performance in extremely low temperatures |

| Low-Temperature Testing | Ensures functionality in cold environments |

| High-Pressure Gas Testing | Confirms integrity under high-pressure gas |

| High-Temperature Testing | Evaluates performance under high-heat conditions |

Quality Assurance

- Our Stainless Steel Manifold Valves are manufactured to international standards, including ASTM, ASME, BS, MSS, EN, DIN, and WERKSTOFFE.

- Every product undergoes rigorous testing before dispatch to ensure the highest standards of quality and performance.

Popular Stainless Steel Manifold Valve Searches

Here’s a quick guide to popular search terms in stainless steel manifold valves:

- 2 & 3 Valve Options: ss manifold valve size, ss 2-way manifold valve for pressure gauge

- Mounting Types: ss manifold mounted ball valves, stainless steel 5 valve remote mounted

- Applications: stainless steel manifold hydraulic valves, types of manifold valves

- Industry Availability: stainless steel manifold valve distributors, ss manifold valves stockholder

- Chemicals industry

- Fats and fertilizer industry

- Ship building

- Construction industry

- Some of the key features of our superior quality high precision manifold valve design are Units duly designed to withstand system static pressure.

- The manifold valves are manufactured to endure all differential pressure and liquid level application needs.

- Units have been manufactured according to a compact assembly design. This translates into complete products which have a reduced weight and size.

- The design and manufacturing details of the valve manifold units ensure fewer chances of potential leak points.

- All units undergo extensive testing procedures to assess quality and precision before being supplied to customers.

- Units are available in a stainless steel 316 material series design.

- The units have been manufactured to ensure easy installation and hassle free maintenance in aggressive industrial systems.

- Bonnet : back seated blow out proof.

- Spindle : ground and thread rolled. Packing below thread.

- Spindle Tip : non-rotating tip shut-off type & soft seated.

- Dust cap : dust cap protects stem threads from external contamination heat code traceability.

- Size : 1/4″ & 1/2″ & 3/4″

- Custom size available as per requirement

- End Connection : NPT, BSPT, BSP & Socket Weld.

- Working Pressure : 6000 psi (413 bar)

- Temperature Rating : PTFE 450° f(232°c)

- Grafoil 700° f (371°c”)

- Optional sour gas service valves are available confirming to nace mr-01-75

Stem Packing : PTFE, Grafoil. - Orifice : ø4.7

- All valves are 100% factory tested prior to shipment.

Monel :

Grade: Monel 400, Monel K500, Monel R-405

Nickel :

Grade: Nickel 200, Nickel 201

Inconel :

Grade: Inconel 600, Inconel 601, Inconel 625, Inconel 718

Incoloy :

Grade: Incoloy 800, Inconel 800H, 800HT

Hastalloy :

Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X

Titanium :

Grade: Gr1, Gr2, Gr3, Gr5, Gr7, Gr11

Stainless Steel :

Grade: ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 304H, 316H, 316/316L, 321, 330, 347, 309/S, 310/S, 317/L, 333, 410/S, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel :

Grade: ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70

Duplex Steel:

Grade: ASTM / ASME A/SA 182 UNS F44, F45, F51, F53, F55, F60, F61

Alloy Steel:

Grade : ASTM SA 182 – E25, E26, E27, E28, E29B, E30B, E39B, E40B, E36B, E36C, E41B, AISI4130, AISI4140, AISI4340, 42CRMO4, 16MNCR5, 20MNCR5, 21CrMoV57, EN353, EN354, F11, F22, F91, F9, P11, P22, P91, P9, P5, P92, EN42J, EN8, EN19

- Pneumatic seat test is performed at 1/4 of working pressure. Hydrostatic shell test is performed at 1.5 times the working pressure optional test are available upon request.

- Molybdenum disulphide (mo s2)