Best Ball Valve Manufacturers in India

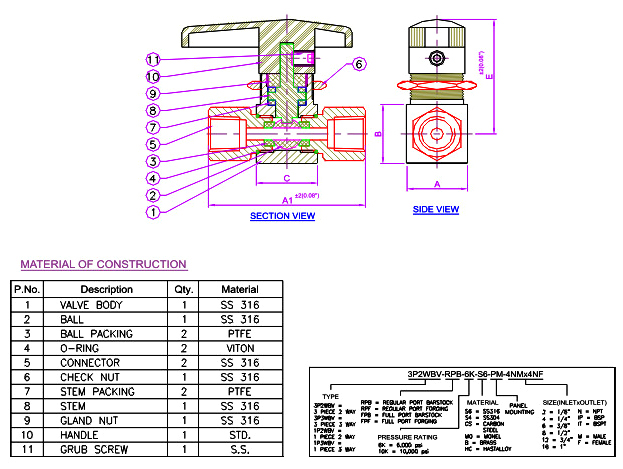

2 WAY BALL VALVE F X F (PANEL MOUNTING), Ball Valve Manufacturers, Suppliers, Exporters in India

Mcneil Instruments is a leading and trusted Ball Valve manufacturers, suppliers, and exporters in India, also manufacturing high performance ball valves in India designed for industrial precision and reliability. Our 2-way panel mount ball valves are engineered using top-grade stainless steel to ensure long-term durability, leak-proof performance, and ease of operation. As one of the trusted names for best quality ball valves, we focus on delivering efficiency in high-pressure environments.

Manufacturing Materials of Ball valves

Ball valves are a type of quarter-turn valve used to control the flow of liquids or gases in a piping system. They consist of a hollow, perforated, and pivoting ball (usually made of metal or plastic) placed inside a valve body with inlet and outlet ports. The ball has a hole, known as the bore, that aligns with the pipeline when the valve is open, allowing fluid or gas to flow through. When the valve is closed, the ball is rotated by 90 degrees, blocking the flow path and sealing off the pipeline.

How Ball Valve Work?

A ball valve is a type of quarter turn valve with a ball inside that has a hole through the middle. When the hole lines up with the flow path, the fluid flows through easily, and the valve is open. When the ball is turned so the hole is perpendicular to the flow path, the fluid can’t pass through, and the valve is closed. The ball is controlled from outside the valve, usually with a handle that can be turned 90 degrees (a quarter turn) to open or close it. This makes ball valves a great choice for shutoff applications. With advances in technology, ball valves can also be used for throttling control and fluid control. Mcneil Instruments is a leading Ball Valve Manufacturers and Ball Valve Exporters in India, known for good quality ball valves Supplier. We offer a wide range of valves designed for various applications, ensuring reliability and durability. Mcneil Instruments combines innovation with customer satisfaction, making them a trusted name in the industry.

Mcneil Instruments Inc is the manufacturer, Supplier and Exporter of ball valves. Bronze, brass, titanium, ductile iron, cast iron, carbon steel, stainless steel, chromium, Teflon, PVC, and other polymers are among the materials that can be used to make ball valves. Every material has something unique to contribute. For example, stainless steel ball valves are certain to have a high tensile strength and be corrosion resistant. PVC ball valves, on the other hand, benefit from all of the advantages of this polymer, including light weight and resistance to chemicals, strong acids, and water.

Our manufactured ball valves are known for their longevity, leak free construction, easy installation, and minimal maintenance requirements. Our adherence to a rigorous testing regimen ensures that each product leaving our facilities upholds the highest standards of performance, durability, and lifespan. As a premier ball valves supplier in India, we contribute significantly to business expansion by offering an unparalleled range of products, competitive pricing, and swift delivery. With an expansive distribution network spanning the nation, we guarantee timely order fulfillment, facilitating seamless operations for your enterprise. Our commitment revolves around unparalleled quality, innovation, and exceptional customer support. as a leading Ball Valve Manufacturers, we are continuously enhancing our product line with advanced features aimed at enhancing efficiency and reducing operational costs showcases our dedication to customer satisfaction. Our team of skilled professionals prioritizes understanding your business’s unique requirements and tailoring solutions accordingly. Mcneil Instruments stands out as an industry leader in ball valve manufacturing, supplying, and exporting by earning trust through product excellence and unwavering commitment to customer satisfaction. Every valve bears our hallmark of quality, craftsmanship, and superior engineering, establishing us as your trusted partner in achieving success.

Products

Dimensional Table of Ball Valve

| Size (NB) | L±30 | OD±1.0 | T±1.0 | P.C.D±1.0 | No. Of Holes | Holes dia. | R/F Dia. | H±5.0 | HI±5.0 | Torque-Min | Torque-Max |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 15MM | 119.0 | 88.9 | 12.0 | 60.3 | 4.0 | 16.0 | 35.0 | 105.0 | 170.0 | 15.0 | 18.0 |

| 20MM | 119.0 | 98.4 | 13.0 | 69.8 | 4.0 | 16.0 | 43.0 | 105.0 | 170.0 | 15.0 | 20.0 |

| 25MM | 127.0 | 108.0 | 13.0 | 79.4 | 4.0 | 16.0 | 51.0 | 105.0 | 200.0 | 20.0 | 22.0 |

| 32MM | 165.0 | 115.0 | 16.0 | 89.0 | 4.0 | 16.0 | 64.0 | 125.0 | 200.0 | 20.0 | 23.0 |

| 40MM | 165.0 | 127.0 | 16.0 | 98.4 | 4.0 | 16.0 | 73.0 | 125.0 | 275.0 | 22.0 | 25.0 |

| 50MM | 178.0 | 152.4 | 18.0 | 120.6 | 4.0 | 19.0 | 92.1 | 134.0 | 320.0 | 30.0 | 33.0 |

| 65MM | 190.0 | 177.8 | 23.0 | 139.7 | 4.0 | 19.0 | 105.0 | 156.0 | 320.0 | 22.0 | 26.0 |

| 80MM | 203.0 | 190.5 | 23.0 | 152.4 | 4.0 | 19.0 | 127.0 | 156.0 | 470.0 | 22.0 | 26.0 |

| 100MM | 229.0 | 228.6 | 24.0 | 190.5 | 8.0 | 19.0 | 157.0 | 230.0 | 600.0 | 25.0 | 28.0 |

| 150MM | 267.0 | 279.6 | 24.0 | 241.3 | 8.0 | 22.0 | 216.0 | 298.0 | 700.0 | 30.0 | 35.0 |

| 200MM | 360.0 | 342.9 | 28.0 | 298.4 | 8.0 | 22.0 | 270.0 | 320.0 | 700.0 | 40.0 | 46.0 |

Types of Ball Valves

Ball Valve Type A

| Connection Size | 1/4″ – 2″ |

| Pressure Rating | Up to 2000 psi |

| Temp. Range | -40°C up to 230°C |

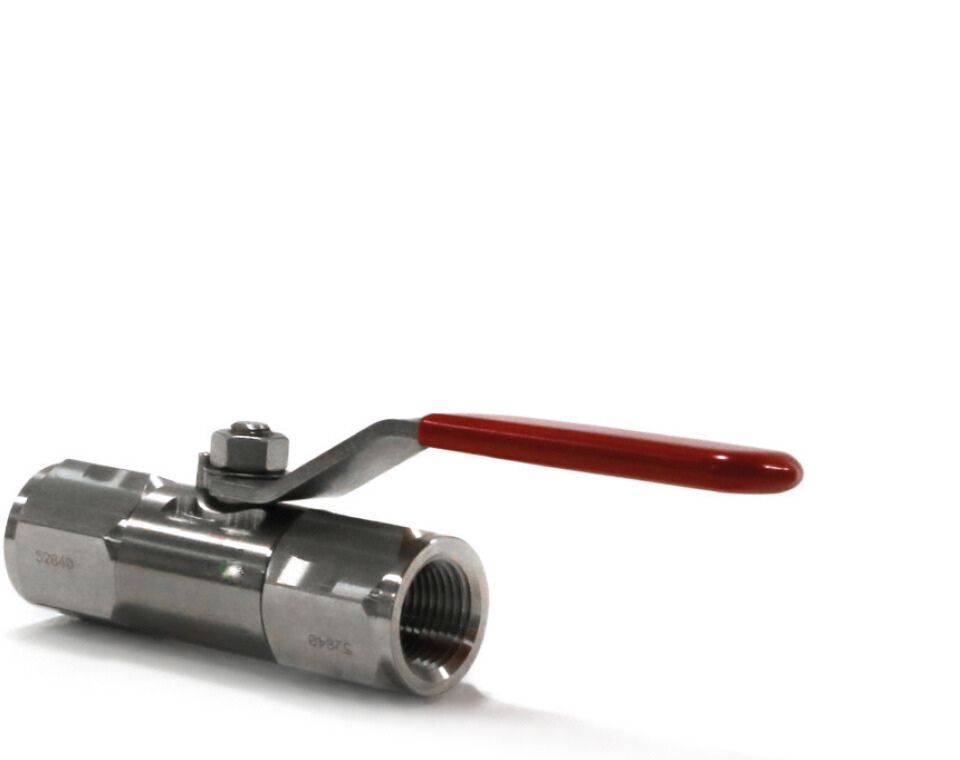

Ball Valve Type B

| Connection Size | 1/2″ – 2″ |

| Pressure Rating | 1000 – 3000 psi |

| Temp. Range | -40°C up to 150°C |

The original three-piece screw-together bar stock series of valves is the “B” Series. a flexible design with a wide range of end connector combinations.

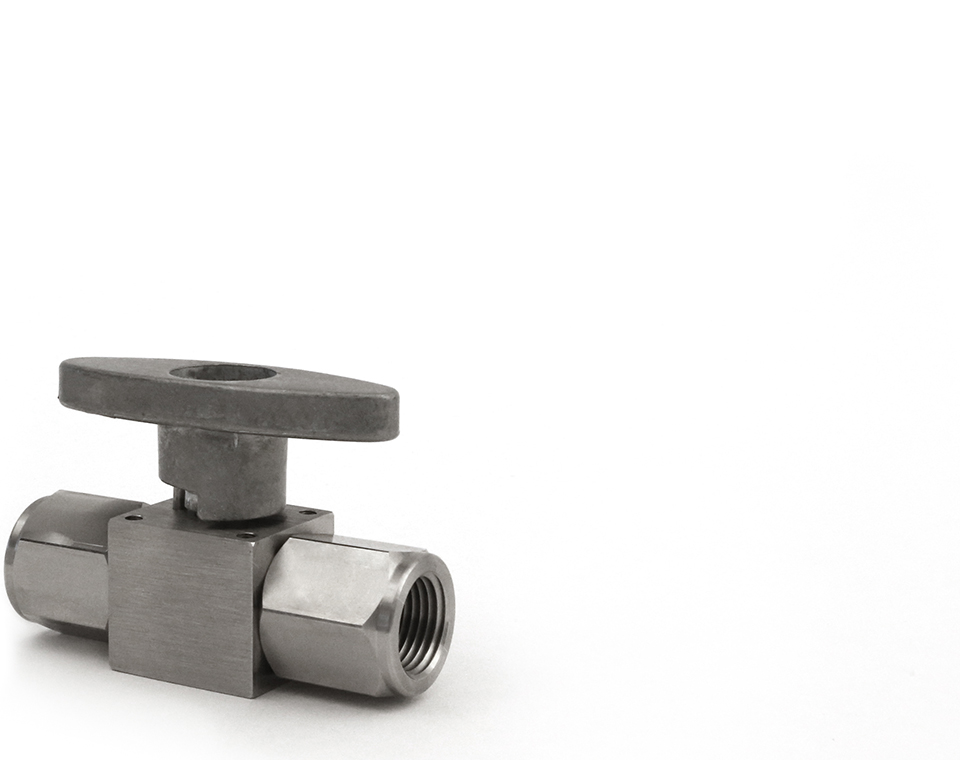

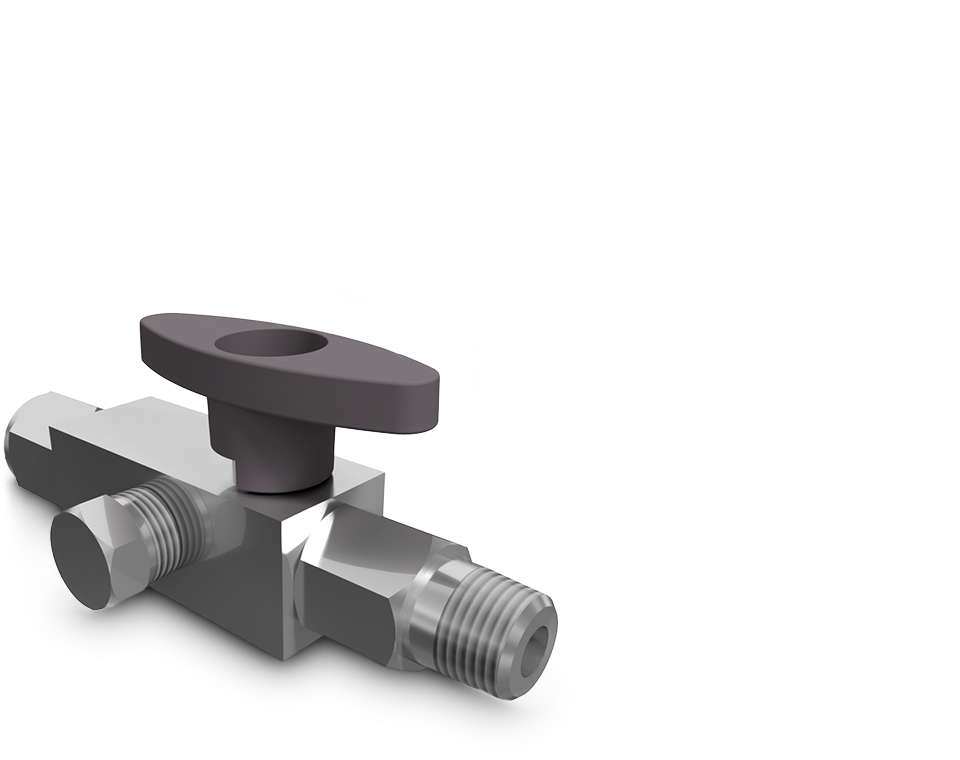

Ball Valve Type SB

| Connection Size | 1/2″ – 1″ |

| Pressure Rating | 1000 – 3000 psi |

| Temp. Range | -20°C up to 110°C |

The Panel Mount, or “SB” series, is an adaptation of the basic “B” series and, as such, maintains the normal “B” series’ flexibility of end connections with the benefit of panel mounting on a flat face. The valve is simple to mount to a control panel or actuator using its flat face.

Ball Valve Type S

| Connection Size | 1/4″ – 2 1/2″ |

| Pressure Rating | 1000 – 3000 psi |

| Temp. Range | -20°C up to 110°C |

The “S” Series, which fastens together, enables interchangeability and versatility. After installation, it is simply maintained by taking out the center part to replace the seats and seals, extending the life of the valves. The ‘Bolt together’ architecture makes it easily convertable to actuator control.

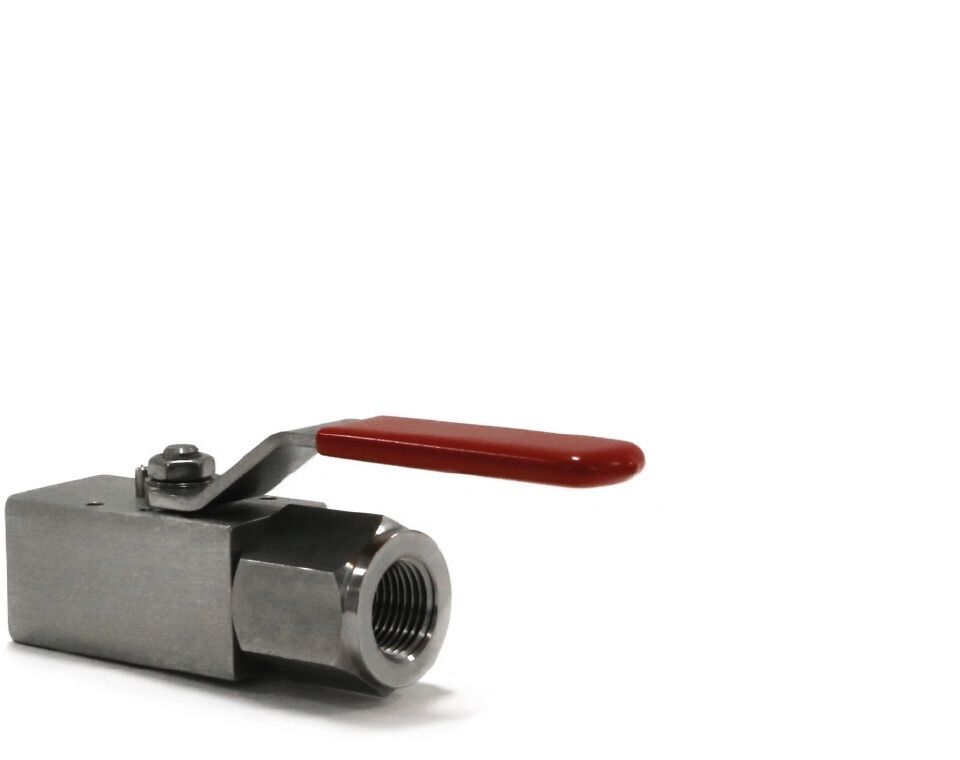

Ball Valve Type PB

| Connection Size | 1/4″ – 2″ |

| Pressure Rating | Up to 6000 psi |

| Temp. Range | -40°C up to 150°C |

The ‘PB’ Series is a high pressure 3 piece ball valve rated at 6000 psi, the ‘PB’ Series is a reliable, compact and flexible isolation ball valve and is the original 3-piece screw together bar stock range of valve. A flexible design with many possible combinations of end connectors available.

Ball Valve Type SN

| Connection Size | 1/4″ – 1″ |

| Pressure Rating | Up to 6000 psi |

| Temp. Range | -40°C up to 150°C |

The single nut mounted ball valve is rated from vacuum up to 6000 psi dependent of seat selection. The single nut allows fast panel mounting. Max panel thickness is 11mm (dependent on valve size). A heavy duty yet compact design offering easy installation and maintainability.

Ball Valve Type 3

| Connection Size | 1/4″ – 1″ |

| Pressure Rating | 1000 – 6000 psi |

| Temp. Range | -20°C up to 110°C |

A convenient way to attach gauges with the ability to test and calibrate gauges and pressure switches is provided by the multiport gauge (ball valve).

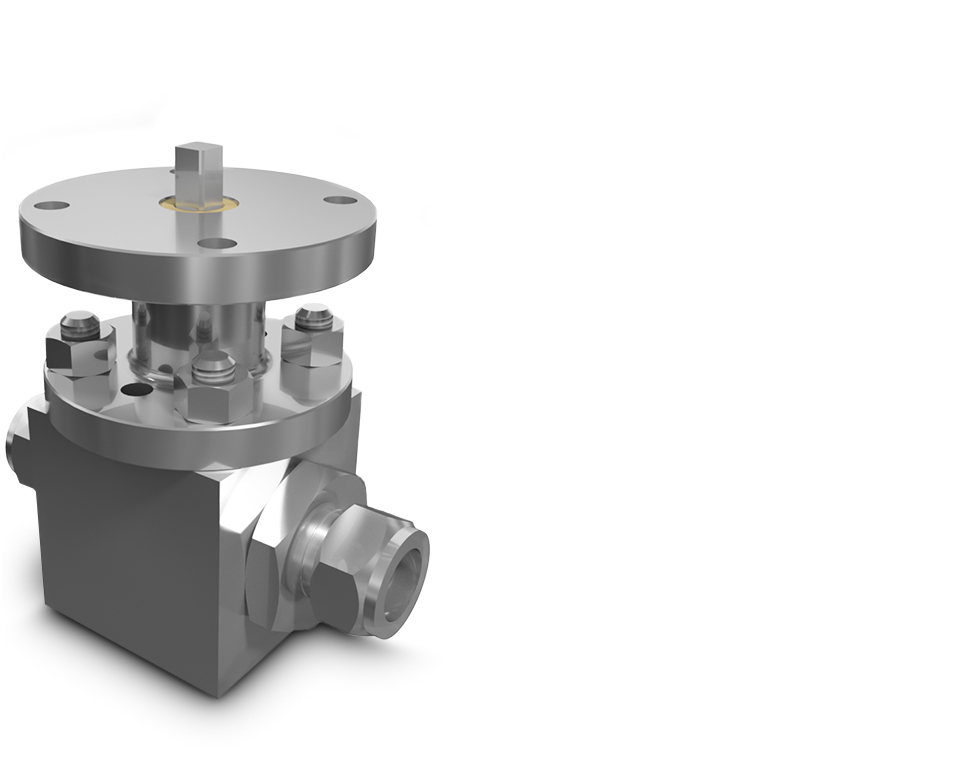

Ball Valve Type Centurion™

| Connection Size | 1/2″ – 1″ |

| Pressure Rating | 6000 psi |

| Temp. Range | -20°C up to +70°C |

The Mcneil Instruments Inc. valve was initially created and developed as the main isolation valve for loading public utility vehicles that are powered by natural gas. a task where the most important considerations are valve safety and reliability.

Ball Valve Type UE

| Connection Size | 1/4″ – 1″ |

| Pressure Rating | 10,000 psi |

| Temp. Range | -40°C up to 230°C |

The tiny ‘UE’ Series combines ball valves from the ‘A’ and ‘B’ series. It is meant to be more compact and lightweight than the ‘UB’ Series. A panel cannot be mounted to the UE series.

Ball Valve Type UB

| Connection Size | 1/4″ – 3/4″ |

| Pressure Rating | 10,000 psi |

| Temp. Range | -40°C up to 230°C |

Mcneil instruments Inc. has created the “UB” Series of valves to meet these demanding specifications because they are aware of the continuously rising working pressures required by the industry. The UB series can be mounted on a panel.

Ball Valve Type 3-Way SB

| Connection Size | 1/4″ – 1″ |

| Pressure Rating | 1000 – 3000 psi |

| Temp. Range | -20°C up to 110°C |

When many high 2-way valves may have been employed, the 3-way L-Port diverter valves provide a safe technique to divert high pressure lines.

Ball Valve Type 3-Way PSB

| Connection Size | 1/4″ – 1″ |

| Pressure Rating | 6000 psi |

| Temp. Range | -40°C up to 150°C |

The need of many high pressure 2-way valves is avoided by using the 3-way L-Port diverter valves, which are a safe approach to redirect high pressure lines.

Ball Valve Type 3T

| Connection Size | 1/4″ – 1″ |

| Pressure Rating | 6000 psi |

| Temp. Range | -40°C up to 150°C |

The ‘3T’ Series “T” ports high pressure diverting ball valve line from Mcneil Instruments Inc. provides a portable and secure solution to regulate, vent, or sample high pressure liquid or gas media. The “3T” is made of high integrity bar-stock material and can be used in hostile conditions.

Ball Valve Type 3-Way USB

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 10,000 psi |

| Temp. Range | -40°C up to 150°C |

The 3-way ‘USB’ L-Port Diverting ball valve series (bottom entry) with 180° and 90° action features low torque, floating seat design, 4-piece flexibility, and single nut panel attachment. The ‘USB’ family is a portable means to safely divert high pressure lines thanks to its Trunnion Mounted Ball construction.

Ball Valve Type X4

| Connection Size | 1/4″ – 1″ |

| Pressure Rating | 6000 psi |

| Temp. Range | -40°C up to 150°C |

A secure technique to redirect high pressure lines is with 4-way multi diverter valves. Several high pressure 2-way valves are replaced by this. Perfect for venting or dumping purposes.

| Valve Series | Type | Connection Size | Pressure Rating | Mounting | Industry Use |

|---|

| A Series | 2-Way FXF | ¼” – 2” | Up to 2000 PSI | No | Instrumentation panels, general utility |

| B Series | 3-Piece | ½” – 2” | 1000 – 3000 PSI | No | Chemical pipelines, hydraulic skids |

| SB Series | Panel Mount | ½” – 1” | 1000 – 3000 PSI | Yes | Control panels, gas sampling systems |

| UB Series | 2-Way/3-Way | ¼” – ¾” | 10,000 PSI | Yes | Oil & gas, marine systems |

| Centurion™ | Special Utility | ½” – 1” | 6000 PSI | Yes | CNG refueling, gas loading valves |

| X4 Series | 4-Way Diverter | ¼” – 1” | 6000 PSI | No | Dump/vent systems, pressure redirection |

2 Way Ball Valve | 3 Way Ball Valve | 4 Way Ball Valve

Ball valves are typically robust and durable, making them suitable for a wide range of applications and environments, including high-pressure and high-temperature conditions.Ball valves are available in various sizes, materials, and configurations to accommodate different fluid types, pressures, and temperatures. They can be used in both residential and industrial applications, including water distribution systems, oil and gas pipelines, chemical processing plants, and HVAC systems. Ball valves can be quickly opened or closed with a 90-degree turn of the handle or lever, making them ideal for applications where fast shut-off is required.

The design of the ball valve provides a tight seal when closed, minimizing leakage and ensuring reliable shut-off of flow. Due to their simple design and fewer moving parts, ball valves require minimal maintenance compared to other types of valves, reducing downtime and operating costs.Ball valves are popular in many industries due to their reliability, versatility, and ease of operation, making them a preferred choice for controlling flow in piping systems.

Mcneil Instrument, is known for its excellence in engineering and commitment to quality, emerges as a top player in the ball valve industry in India. we are a top Ball Valve Manufacturers and Ball Valve Suppliers in india, Mcneil Instrument offers a comprehensive range of ball valves manufactured to precision and designed to meet diverse industrial needs. With a focus on superior performance and reliability, our ball valves stand out as some of the best in the market. As trusted Ball Valve Exporters in India, Mcneil Instrument extends its reach globally, providing top-notch ball valves to clients worldwide. Whether you’re seeking reliable suppliers, manufacturers, or exporters of ball valves in India, Mcneil Instrument remains a preferred choice, ensuring top-quality products and exceptional service to meet your requirements effectively.

Two-way, three-way, and four-way ball valves in L, T, and LL port designs are available from Mcneil Instruments Inc. Ball valves are particularly unique in that they can control the flow of a line fluid in a L shape (90 degrees), an LL shape for media flow line diversion, and a T shape for additional line flow controls at 90 degrees. According to the applications of the valves, we use stainless steel 304 and 316 grade internals. Our valves are utilized in hazardous media and extremely corrosive applications.

Ball Valve 2 Way Manufacturers

A 2-way ball valve is one of the most commonly used types of industrial ball valves. It has two ports – an inlet and an outlet – and is designed for on/off control of fluid flow in a straight line. These valves are widely used in chemical, petrochemical, water treatment, HVAC, and general industrial applications due to their simple design and durable performance.

Features of 2-Way Ball Valves:

- Full bore or reduced bore design

- Quarter-turn operation for quick shutoff

- Available in stainless steel, brass, or carbon steel

- Pressure rating: Up to 6000 PSI depending on the design

- Ends: Threaded, socket weld, or flanged

Alternatives to 2-Way Ball Valves:

- 3-Way Ball Valve: Diverts flow between two outlets or mixes two inlets

- 4-Way Ball Valve: Used for complex flow routing in hydraulic or pneumatic systems

Mcneil Instruments is a trusted ball valve 2 way manufacturer, delivering high-performance solutions with precision-engineered construction and leak-proof sealing, suitable for harsh industrial environments.

90 Degree Ball Valve Supplier

A 90-degree ball valve refers to a valve with a quarter-turn (90° rotation) of the handle to fully open or close the valve. While the term “90-degree” often describes the rotation angle, in some industries it also refers to the L-shaped body configuration or angle pattern used in piping layouts with tight corners.

These valves are ideal for applications where space-saving and directional flow changes are critical.

Features of 90-Degree Ball Valves:

- Quick 90° handle rotation for on/off control

- Compact design, ideal for space-restricted installations

- Available with male/female threads or flanged ends

- Often used in plumbing, food processing, marine systems

Applications:

- Skid-based systems

- Compact fluid distribution panels

- Space-sensitive industrial layouts

Mcneil Instruments is a reliable 90-degree ball valve supplier, offering valves that ensure smooth operation, high flow capacity, and corrosion resistance, tailored for both low and high-pressure applications.

Ball Valve Manufacturers in India.

As the best ball valve manufacturers in India, we use authentic, guaranteed raw materials and have material and hydraulic test certificates for manufacturing ball valves. Mcneill Instruments Inc. has an in-house cryogenic testing facility for ball valves, which is specifically designed to measure leaks in any type of ball valve (floating or trunnion mounted), at any temperature down to -196 degrees Celsius. BS 6364 / BS EN 1626 is the standard reference for cryogenic testing of ball valves. Cryogenic ball valves are tested under pressure using the valve’s specific class as a reference. In order to position the stem packing above the cryogenic fluid and create a column of warmer vapor that insulates the stem packing from any effects caused by low temperature, all of these cryogenic ball valves are manufactured with an extended stem and bonnet.

Best Ball valves Suppliers in India.

Our premium selection of Two Way, Three Way, and Four Way Ball Valves is specifically made for the steel, petrochemical, chemical, fire safety, and shipping industries, among other industries. The vast majority of our clientele adore our Ball Valve because they are very well-made. We supply all ball valves to more than 35 countries and have clients who regularly require Two Way Ball Valve, Three Way Ball valve, Four Way Ball Valve in various regions.

Trusted Local Manufacturer, Supplier & Exporter of Ball Valve in India

Mcneil Instruments is a reliable local supplier and exporter of ball valve in India, catering to diverse industrial requirements with a focus on quality and precision. As leading instrumentation valve manufacturers in Chennai, we deliver products tailored for high-performance applications in oil & gas, power, and chemical sectors. Our strong presence as instrumentation valve manufacturers in Ahmedabad and industrial instrumentation valve manufacturers in Ahmedabad reinforces our commitment to supplying durable and efficient valve and fitting solutions across India and abroad.

Best Ball valves Exporters in India.

Mcneil Instruments Inc. Export Ball Valves to Kazakhstan, Algiers, Johannesburg, Ghana, Uganda, Iraq, Subra al-Haymah, Australia, Yaounda, South Africa, Saudi Arabia, Ethiopa, Kuwait, Luanda, Abu Dhabi, Peru, Sudan, Colombia, Nairobi, Turkey, Russia, Khartoum, Kano, UAE, Bahrain, Cape Town, Trinidad and Tobago, Dar es Salaam, Nigeria, Antananarivo, Tripoli, Addis Ababa, London, Douala, Lebanon, Tunisia, Ouagadougou, Mogadishu, Harare, Mbuji-Mayi, Qatar, Zaria, Soweto, Omdurman, Angola, Alexandria, Dubai, Yemen, Casablanca, Africa, Oman, Giza, UK, Houston, Accra, Algeria, Argentina, Cairo, Chine, Kolwezi, Hong Kong, Abidjan, Vietnam, Port Elizabeth, Maputo, Canada, Port Harcourt, Singapore, Egypt, Venezuela, Freetown, Ibadan, Iran, Malaysia, Mexico, Cameroon, New York, Indonesia.

Product Applications

Ball valves are used in many industries because they are reliable and easy to use. They are commonly found in oil and gas, water treatment, chemical processing, and manufacturing. Ball valves control the flow of liquids and gases, making them essential for pipelines, plumbing systems, and industrial machinery. They are also used in food and beverage production to manage fluid flow and ensure sanitary conditions. The simplicity and efficiency of ball valves make them a popular choice for many different applications. Mcneil Instruments excels in providing good quality ball valves for these varied applications. As a Best Ball Valve Manufacturers and Ball Valve Suppliers in India, Oue product is Known for precision and durability, Mcneil Instruments’ products are trusted by industries worldwide to deliver superior performance and reliability.

Ball Valve Manufacturers in india, Ball Valve Exporters, Ball Valve Suppliers in india, Best Ball Valve Exporters, Ball Valve Manufacturers, Best Ball Valve Produser in India, Ball Valve Suppliers, Ball Valve Exporters in India

Mcneil Instrument’s floating ball valve stands out as a versatile solution acclaimed for its dependable performance and effective flow control. Featuring a ball design, this valve facilitates unrestricted ball movement, ensuring tight seals and decreased torque demands. Tailored for a multitude of industries including oil and gas, chemical, and water treatment, Mcneil Instrument’s floating ball valve delivers outstanding shut-off capabilities, minimal pressure loss, and simplified maintenance procedures. Boasting a wide array of material selections, sizes, and pressure ratings, it caters to diverse applications, offering dependable and economical valve solutions.

At Mcneil Instruments, we understand the distinct requirements of every industry, and we customize our offerings to ensure your operations stay streamlined, economical, and seamless. Our extensive range of products, featuring bronze, carbon steel, and stainless steel ball valves, caters to the specific needs of diverse sectors. Collaborate with us for your ball valve necessities and experience the optimal blend of excellence, performance, and affordability. What sets us apart from other ball valve manufacturers and suppliers in India is our unwavering commitment to exceeding customer anticipations. Contact us today to discover how Mcneil Instrument can fulfill your ball valve needs with excellence and reliability.

Top Features of Mcneil Instruments’ High-Performance Ball Valves

- Premium Quality Manufacturing: As a leading Ball Valve Manufacturer, Mcneil Instruments produces robust valves from certified materials, ensuring durability and reliable performance.

- Extensive Testing for Reliability: Every ball valve undergoes rigorous material and hydraulic testing, with specialized cryogenic testing down to -196°C, meeting BS 6364 / BS EN 1626 standards.

- Versatile Range for Multiple Industries: Offering Two-Way, Three-Way, and Four-Way Ball Valves, Mcneil Instruments meets the diverse needs of steel, petrochemical, chemical, fire safety, and shipping industries.

- Global Reach and Export Excellence: Trusted by clients in over 35 countries, including South Africa, UAE, and Singapore, Mcneil Instruments is a leading Ball Valve Exporter recognized worldwide for quality.

- Reliable, Leak-Free Design: Known for their leak-proof construction and easy installation, Mcneil’s ball valves ensure dependable fluid control and low-maintenance solutions.

- Commitment to Customer Satisfaction: With a focus on timely delivery and tailored solutions, Mcneil Instruments prioritizes customer satisfaction, making them a top Ball Valve Supplier in India.

Choosing the Right Ball Valve Series”

With a wide range of pressure ratings, flow configurations, and body materials, Mcneil Instruments offers a ball valve for nearly every industrial need. Whether you need a panel-mounted valve for a compact instrumentation cabinet, or a high-pressure diverter valve for offshore fluid systems, we have a product tailored to your environment. Selecting the correct series ensures operational safety, ease of installation, and minimal maintenance

Choose PB or UB series for high-pressure gas isolation

Use SB or SN series for compact control panels

Use 3T or X4 series for diverting/venting in multi-port layouts

Centurion™ series is ideal for public gas fueling infrastructure

- Chemicals industry

- Fats and fertilizer industry

- Ship building

- Construction industry

- SS 316 construction for corrossion resistance, full or reduced bore for excellent flow.3 piece design.peek/delrin seat for better performance.

- Ball hard chrome plated for smooth operation.

Pressure rating 400 kg/cm2

- For seat and seal leakage with a leakage rate of 0.1 std. Cm3.

- Working pressure : 6000 psi (431 bar)

- Performed with pure water at 1-1/2 times of the working pressure.

- Other tests like helium, seismic are availbale upon request.

Monel :

Grade: Monel 400, Monel K500, Monel R-405

Nickel :

Grade: Nickel 200, Nickel 201

Inconel :

Grade: Inconel 600, Inconel 601, Inconel 625, Inconel 718

Incoloy :

Grade: Incoloy 800, Inconel 800H, 800HT

Hastalloy :

Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X

Titanium :

Grade: Gr1, Gr2, Gr3, Gr5, Gr7, Gr11

Stainless Steel :

Grade: ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 304H, 316H, 316/316L, 321, 330, 347, 309/S, 310/S, 317/L, 333, 410/S, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel :

Grade: ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70

Duplex Steel:

Grade: ASTM / ASME A/SA 182 UNS F44, F45, F51, F53, F55, F60, F61

Alloy Steel:

Grade : ASTM SA 182 – E25, E26, E27, E28, E29B, E30B, E39B, E40B, E36B, E36C, E41B, AISI4130, AISI4140, AISI4340, 42CRMO4, 16MNCR5, 20MNCR5, 21CrMoV57, EN353, EN354, F11, F22, F91, F9, P11, P22, P91, P9, P5, P92, EN42J, EN8, EN19