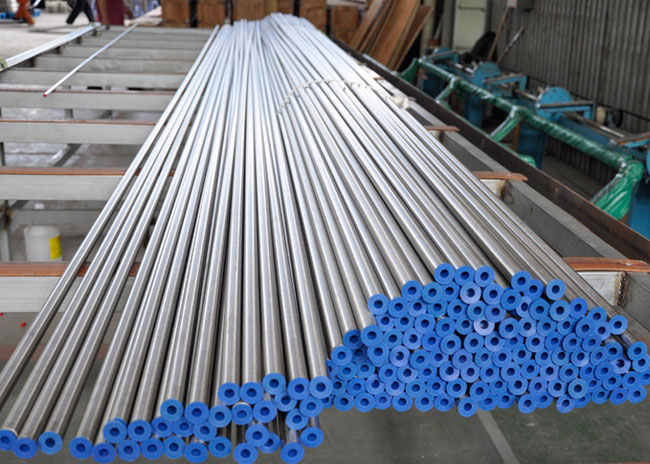

STAINLESS STEEL SEAMLESS TUBE

Mcneil Instruents Inc. is one of the Best leading Stainless Steel Tube manufacturers, Suppliers and Exporters in India. Stainless Steel Seamless Tube is made up of stainless steel materials. There are different stainless steel grades. The 304 grade is the most used and the 304 stainless steel tubes are cost effective.

There are several different types of stainless steel, including austenitic, duplex, and pipes made of economically pure metal. Mcneil Instrumnts Inc. is a manufacturer of Stainless Steel Seamless tube in different types, shapes and methods. Our stainless steel Seamless tubes are utilized in various applications where easier installation and greater dimensional precision are necessary.

Leading Manufacturer of Stainless Steel Seamless Tube

Mcneil Instrument, a renowned manufacturer, supplier, and exporter in India, specializes in producing high-quality Stainless Steel Seamless Tubes. Our seamless tubes are crafted with precision using premium-grade stainless steel, ensuring exceptional durability, corrosion resistance, and long-lasting performance. With a commitment to delivering excellence, we cater to various industries, offering a wide range of sizes, grades, and specifications to meet diverse application requirements. As a trusted manufacturer, Mcneil Instrument prioritizes stringent quality control measures, ensuring that our Stainless Steel Seamless Tubes adhere to international standards and surpass customer expectations. Whether you need tubes for fluid transportation, heat exchangers, or structural applications, our seamless tubes provide reliable and efficient performance in demanding environments. Rely on Mcneil Instrument for top-notch Stainless Steel Seamless Tubes that guarantee superior quality, strength, and reliability for your projects.

Stainless Steel Seamless Tube Tolerances

| NPS Designator | Permissible Variations in Outside Diameter | |

|---|---|---|

| Over In. | Under In. | |

| 1/8 to 1-1/2, incl | 1/64 (0.015) | 1/32 (0.031) |

| Over 1-1/2 to 4, incl | 1/32 (0.031) | 1/32 (0.031) |

| Over 4 to 8, incl | 1/16 (0.062) | 1/32 (0.031) |

| Over 8 to 18, incl | 3/23 (0.093) | 1/32 (0.031) |

Stainless Steel Seamless Tubes Specification

Specification Format of Stainless Steel Seamless Tubes:-

| Specification Aspect | Description |

|---|---|

| Standard | ASTM, ASME, JIS, EN, DIN, etc. |

| Material Grade | 304, 304L, 316, 316L, 321, 347, 310S, etc. |

| Outer Diameter (OD) | Specified in inches or millimeters (e.g., 1/8″ to 24″ or 6mm to 610mm) |

| Wall Thickness (WT) | Specified in inches or millimeters (e.g., SCH 5, 10, 40, 80, 160, or 0.5mm to 25mm) |

| Length | Standard lengths (e.g., 6m, 12m) or custom lengths |

| Manufacturing Process | Cold drawn, hot rolled, or cold finished |

| Surface Finish | Annealed and pickled, bright annealed, polished, etc. |

| Mechanical Properties | Yield strength, tensile strength, elongation, hardness |

| Chemical Composition | Percentages of elements like C, Mn, Si, P, S, Cr, Ni, Mo, etc. |

| Testing Requirements | Hydrostatic test, eddy current test, ultrasonic test, etc. |

| Certification | Mill test certificates, third-party inspection reports |

| End Finishes | Plain ends, beveled ends, threaded ends |

| Special Requirements | Tolerances, straightness, ovality, etc. |

Example Specifications Table for a Specific Tube

| Aspect | Specification |

|---|---|

| Standard | ASTM A312 |

| Material Grade | 316L |

| Outer Diameter (OD) | 1″ (25.4 mm) |

| Wall Thickness (WT) | SCH 40 (3.68 mm) |

| Length | 6 meters |

| Manufacturing Process | Cold drawn |

| Surface Finish | Annealed and pickled |

| Mechanical Properties | Yield strength: 205 MPa, Tensile strength: 515 MPa, Elongation: 35%, Hardness: 90 HRB |

| Chemical Composition | C: 0.03%, Mn: 2.00%, Si: 0.75%, P: 0.045%, S: 0.03%, Cr: 16.00-18.00%, Ni: 10.00-14.00%, Mo: 2.00-3.00% |

| Testing Requirements | Hydrostatic test, Eddy current test |

| Certification | Mill test certificate |

| End Finishes | Plain ends |

| Special Requirements | Dimensional tolerances as per ASTM A999 |

Stock of Stainless Steel Seamless Pipe

| SS TP 304 Seamless Pipes | Stainless TP 304L Seamless Tubing |

| ASTM A213 Stainless Welded Pipe | A249 SS TP Welded Tubes |

| ASTM A358 310S Stainless ERW Pipe | A312 SS 310 Rectangular Seamless Pipe |

| ASTM A213 316 SS Rectangular Tubes | TP 316L SS ERW Tubes |

| TP 316H Stainless Coiled Seamless Tubing | SS Heat Ex-changer Tubes |

| Stainless 317L Round Tubing | ASTM A213 317 Stainless Square Seamless Pipes |

| ASME TP Stainless Electric Fusion Welding Pipes | TP 321 SS EFW Tubing |

Schedule List of Stainless Steel Seamless Tubes

| Schedule | Outer Diameter (OD) | Wall Thickness (WT) |

|---|---|---|

| SCH 5 | 1/8″ to 24″ | 0.035″ to 0.500″ |

| SCH 10 | 1/8″ to 24″ | 0.049″ to 0.500″ |

| SCH 20 | 1/8″ to 24″ | 0.065″ to 0.500″ |

| SCH 30 | 1/8″ to 24″ | 0.083″ to 0.500″ |

| SCH 40 | 1/8″ to 24″ | 0.109″ to 0.500″ |

| SCH 60 | 1/8″ to 24″ | 0.134″ to 0.500″ |

| SCH 80 | 1/8″ to 24″ | 0.154″ to 0.500″ |

| SCH 100 | 1/8″ to 24″ | 0.179″ to 0.500″ |

| SCH 120 | 1/8″ to 24″ | 0.218″ to 0.500″ |

| SCH 140 | 1/8″ to 24″ | 0.250″ to 0.500″ |

| SCH 160 | 1/8″ to 24″ | 0.281″ to 0.500″ |

| XXS | 1/8″ to 24″ | 0.307″ to 0.500″ |

Stainless Steel Seamless Tube Size Inch

Here’s a detailed table showing the standard sizes of stainless steel seamless tubes in inches, including the outer diameter (OD) and corresponding wall thicknesses for various schedules:

| Nominal Pipe Size (NPS) | Outer Diameter (OD) | SCH 5S | SCH 10S | SCH 40S (STD) | SCH 80S (XS) | SCH 160 | XXS |

|---|---|---|---|---|---|---|---|

| 1/8 | 0.405 | 0.035 | 0.049 | 0.068 | 0.095 | – | – |

| 1/4 | 0.540 | 0.049 | 0.065 | 0.088 | 0.119 | – | – |

| 3/8 | 0.675 | 0.049 | 0.065 | 0.091 | 0.126 | – | – |

| 1/2 | 0.840 | 0.065 | 0.083 | 0.109 | 0.147 | – | – |

| 3/4 | 1.050 | 0.065 | 0.083 | 0.113 | 0.154 | – | – |

| 1 | 1.315 | 0.065 | 0.109 | 0.133 | 0.179 | – | – |

| 1 1/4 | 1.660 | 0.065 | 0.109 | 0.140 | 0.191 | – | – |

| 1 1/2 | 1.900 | 0.065 | 0.109 | 0.145 | 0.200 | – | – |

| 2 | 2.375 | 0.065 | 0.109 | 0.154 | 0.218 | – | – |

| 2 1/2 | 2.875 | 0.083 | 0.120 | 0.203 | 0.276 | – | – |

| 3 | 3.500 | 0.083 | 0.120 | 0.216 | 0.300 | – | – |

| 3 1/2 | 4.000 | 0.083 | 0.120 | 0.226 | 0.318 | – | – |

| 4 | 4.500 | 0.083 | 0.120 | 0.237 | 0.337 | 0.438 | 0.531 |

| 5 | 5.563 | 0.109 | 0.134 | 0.258 | 0.375 | 0.500 | 0.625 |

| 6 | 6.625 | 0.109 | 0.134 | 0.280 | 0.432 | 0.562 | 0.718 |

| 8 | 8.625 | 0.109 | 0.148 | 0.322 | 0.500 | 0.718 | 0.906 |

| 10 | 10.750 | 0.134 | 0.165 | 0.365 | 0.500 | 0.843 | 1.000 |

| 12 | 12.750 | 0.156 | 0.180 | 0.406 | 0.500 | 0.937 | 1.000 |

| 14 | 14.000 | 0.156 | 0.188 | 0.437 | 0.500 | 0.875 | – |

| 16 | 16.000 | 0.165 | 0.188 | 0.500 | 0.500 | 0.937 | – |

| 18 | 18.000 | 0.165 | 0.188 | 0.562 | 0.500 | 1.000 | – |

| 20 | 20.000 | 0.188 | 0.218 | 0.593 | 0.500 | 1.062 | – |

| 24 | 24.000 | 0.218 | 0.250 | 0.687 | 0.500 | 1.250 | – |

This table provides a comprehensive overview of the sizes and wall thicknesses for various schedules of stainless steel seamless tubes, helping you choose the right specifications for your needs.

Mcneil instruments provide their services all over the world. We are supplying it to their esteemed and valued clients with the best prices and services. These Stainless Steel Tubes are available from us at very competitive and suitable pricing. All our products are designed and developed using high-grade raw material and latest technology to ensure that final output meets with international quality norms & standards. Moreover, we check all products on various parameters to assure zero defect.

Key Standards for Stainless Steel Tubes and Pipes (ASTM, DIN, NF, JIS)

(A) ASTM/ASME – Standards | ||

A | 213 / SA 213 | Seamless ferritic and austenitic alloy steel boiler, super heater and heat Exchanger Tubes |

A | 249 / SA 249 | Welded austenitic steel boiler, Super Heater, Heat Exchanger Tubes and Condenser Tubes |

A | 268 / SA 268 | Seamless and Welded ferritic and martensitic stainless steel tubing for general service |

A | 269 / SA 269 | Seamless and Welded austenitic stainless steel tubing for general service |

A | 312 / SA 312 | Austenitic stainless steel seamless pipe & S.S. Welded pipes |

A | 358 / SA 358 | Stainless Steel Welded pipe for high temperature service |

A | 688 / SA 688 | Welded feed water heater ‘U’ Tubes |

(C) German – Standards | ||

DIN | 17455 | Welded general purpose piping |

DIN | 17456 | Seamless circular austenitic stainless steel for general service |

DIN | 17457 | Circular austenitic stainless steel welded tubes subject to special requirement |

DIN | 17458 | Seamless circular austenitic stainless steel tubes subject to special requirement |

DIN | 28180 | Stainless Steel Seamless Heat Exchanger Tube |

(D) NF – Standards (AFNOR Standard) | ||

NF | A 49-117 | Seamless ferritic and austenitic stainless steel tubes for general services |

NF | A 49-217 | Seamless ferritic, austenitic and ferritc-austenitic stainless steel tubes for heat exchanger |

(F) JIS – Standards | ||

JIS | G 3459 | S.S. Seamless pipes. |

JIS | G 3463 | Stainless steel boiler and heat exchanger tubes |

Products

- Corrosion resistant

- Temperature resistant

- Easy formability and fabrication

- Low-maintenance (long lasting)

- Attractive appearance

- Environmentally friendly (recyclable)

- Durable

- High tensile strength

- Longer service life

- Minimal maintenance

The cleanliness and purity of materials that come into direct touch with stainless steel can be ensured by stainless steel seamless tube’s resistance to high temperatures. Stainless steel tubing is applied in chemical facilities, aviation areas, marine equipment, cryogenic transportation, medicinal and architectural industries.

- Chemical plants

- Aviation fields

- Marine equipment

- Medical & architectural industries

- Cryogenic transportation

| Product Name | Exucative Standard | Dimension | Steel Grade |

| Seamless Austenitic Stainless Steel Pipes | ASTM A312/A312M, ASME SA312/SA312M | OD: 6.0~914.0mm WT: 0.5~88mm | TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| Seamless Austenitic Stainless Steel Tubing for General Service | ASTM A269, ASME SA269 | OD: 6.0~50.8mm WT: 0.8~10.0mm | TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| Seamless Austenitic Alloy-Steel Boiler, Super Heater and Heat-Exchanger Tubes | ASTM A213/A213M, ASME SA213/SA213M | OD: 6.0~50.8mm WT: 0.8~10.0mm | TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| Seamless Duplex Stainless Steel Tubing for General Service | ASTM A789 / A789M | OD: 19.0~60.5mm WT: 1.2~5.0mm | S31803, S32205, S32750 |

| Seamless Duplex Stainless Steel Pipes | ASTM A790 / A790M | OD: 3/4″~10″ WT: SCH5S~SCH80S | S31803, S32205, S32750 |

| Seamless Stainless Steel Mechanical Tubing | ASTM A511 | OD: 6.0~50.8mm WT: 1.8~10.0mm | MT304, MT304L, MT304H, MT310, MT310S, MT316, MT316L, MT317, MT317L, MT321, MT321H, MT347 |

| Seamless Stainless Steel Tubes for Pressure Purposes | EN 10216, DIN 17456, 17458 | OD: 6.0~914.0mm WT: 0.5~88mm | 1.4301, 1.4307, 1.4541, 1.4401, 1.4404, 1.4571, 1.4878, 1.4432, 1.4462 |

| Steel No. | Type | Chemical composition | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | S | P | Mn | Cr | Ni | Mo | Other | ób | ós | δ5 | HB | ||

| TP304 | 0.08 | 0.75 | 0.03 | 0.04 | 2 | 18-20 | 8-11 | 515 | 205 | 35 | ||||

| TP304H | 0.04-0.1 | 0.75 | 0.03 | 0.04 | 2 | 18-20 | 8-11 | 515 | 205 | 35 | ||||

| TP304L | 0.035 | 0.75 | 0.03 | 0.04 | 2 | 18-20 | 8-13 | 485 | 170 | 35 | ||||

| TP316L | 0.035 | 0.75 | 0.03 | 0.04 | 2 | 16-18 | 10-15 | 2-3 | 485 | 170 | 35 | |||

| TP321 | 0.08 | 0.75 | 0.03 | 0.04 | 2 | 17-20 | 9-13 | Ti:5C%-0.7 | 515 | 205 | 35 | |||