Best Instrument Air Headers for Petrochemical Plants

In the complex world of petrochemical plants, maintaining precision and reliability in operations is crucial. One key component in ensuring smooth operations is the instrument air header. This air header system plays a vital role in powering and controlling various instruments and control valves that are essential for maintaining the efficiency and safety of a petrochemical plant. Reliable air header manufacturers provide the equipment necessary to achieve these goals. By partnering with trusted air header suppliers and air header exporters, plants can ensure they receive high-quality air headers that support optimal performance and operational safety.

What is an Instrument Air Header?

An instrument air header is a crucial part of the infrastructure in petrochemical plants. It is an air distribution manifold designed to supply compressed air to various instruments, controls, and devices throughout the facility. This compressed air powers pneumatic instruments and control valves that regulate processes and ensure the safe and efficient operation of the plant. Air header suppliers ensure that these systems are reliable air headers and up to industry standards.

Components of an Instrument Air Header

- Air Compressors: These machines compress ambient air to a higher pressure, which is then fed into the instrument air header system.

- Air Dryers: Essential for removing moisture from the compressed air, air dryers prevent water vapor from contaminating the system. Moisture can damage instruments and affect their accuracy.

- Air Filters: Filters are used to clean the compressed air by removing particulates and impurities, which is vital for the proper functioning of sensitive instruments.

- Pressure Regulators: These devices maintain the air pressure within the required range, ensuring that instruments and control valves operate correctly.

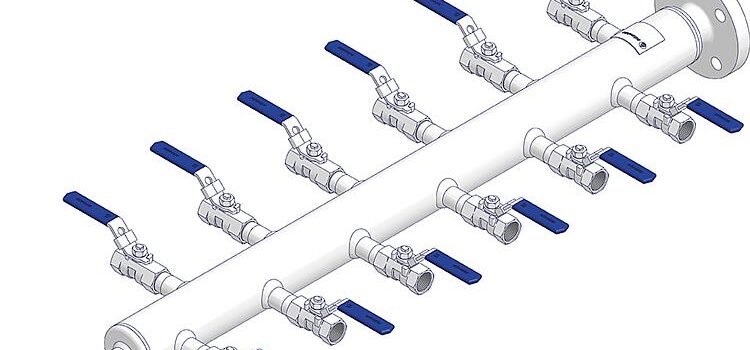

- Piping and Headers: Piping systems distribute the compressed air throughout the plant. Headers are large pipes that collect and distribute air to different branches.

- Control Valves: These regulate the flow of air, allowing for precise control over the distribution to various parts of the plant.

Functions of an Instrument Air Header in Petrochemical Plants

- Reliable Air Supply: The instrument air header ensures a consistent and reliable supply of compressed air to critical instruments and controls throughout the petrochemical plant.

- Pressure Regulation: It maintains the air pressure within a specific range, which is crucial for the accurate operation of pneumatic devices used in controlling plant processes.

- Air Distribution: The header system distributes compressed air to various parts of the plant, ensuring that all necessary instruments and control valves receive the air required for proper functioning.

- Maintenance of Instrument Accuracy: By providing clean, dry, and regulated air, the instrument air header helps maintain the accuracy and reliability of measurement instruments and control systems essential for petrochemical processes.

How Instrument Air Headers are Used in Petrochemical Plants

Instrument air headers are integral to the operation of petrochemical plants due to their role in powering and controlling critical systems. Here’s how they are utilized:

- Process Control: Instrument air headers supply compressed air to pneumatic control valves that regulate the flow of chemicals, gases, and other substances throughout the plant. Accurate control is essential for maintaining process stability and safety.

- Measurement Instruments: Many measurement instruments, such as pressure and temperature transmitters, require a steady supply of compressed air to operate. The air header ensures these instruments function correctly, providing accurate readings that are crucial for process control and monitoring.

- Safety Systems: Safety systems, including emergency shutdown valves and alarms, often rely on compressed air to function. The instrument air header provides the necessary air supply to ensure these systems are operational in case of an emergency.

- Actuators: Pneumatic actuators, which are used to move or control mechanical devices, require compressed air from the instrument air header. These actuators are used in various applications, including valve operation and material handling.

- Cleanliness and Reliability: The air header system ensures that the compressed air is clean and dry, preventing contamination of sensitive instruments and systems. This reliability is crucial for maintaining the efficiency and safety of plant operations.

Benefits of a Well-Designed Instrument Air Header in Petrochemical Plants

- Improved Reliability: A well-designed air header system ensures a constant and reliable supply of air, enhancing the overall reliability of the plant’s control and instrumentation systems. Leading air header exporters offer high-quality air headers that contribute to improved plant performance.

- Enhanced Safety: Proper functioning of safety instruments and control valves, powered by the air header system, is crucial for ensuring the safety of the plant and its personnel.

- Reduced Downtime: Effective design and regular maintenance of the air header system can minimize downtime caused by air supply issues or equipment failures.

- Cost Efficiency: Efficient air distribution and pressure regulation contribute to energy savings and reduced operational costs, which are critical for the economic performance of petrochemical plants.

Best Practices for Instrument Air Header Maintenance

- Regular Inspection: Regularly check the air header system for leaks, blockages, and wear to prevent significant issues.

- Filter and Dryer Maintenance: Follow the manufacturer’s recommendations for replacing or cleaning air filters and dryers to prevent contamination and extend equipment life.

- Pressure Checks: Ensure that pressure regulators and gauges are functioning correctly and maintain air pressure within the desired range.

- Leak Detection: Identify and repair any leaks in the system to avoid loss of compressed air and reduced efficiency.

- System Testing: Periodically test the entire system, including compressors, dryers, filters, and piping, to ensure proper operation.

Challenges in Managing Instrument Air Headers in Petrochemical Plants

- Moisture Control: Managing moisture levels in compressed air is challenging but crucial, as excess moisture can lead to corrosion and damage.

- Pressure Fluctuations: Maintaining consistent pressure can be difficult, especially with varying demand for compressed air in different parts of the plant.

- System Complexity: The complexity of the air header system, with its various components and interactions, can make maintenance and troubleshooting challenging.

- Energy Consumption: Compressing air requires significant energy. Efficient management of the air header system is necessary to control energy consumption and costs.

Why Choose McNeil Instruments for Your Petrochemical Plant?

When selecting an air header system for your petrochemical plant, choosing a trusted name like McNeil Instruments can make a significant difference. McNeil Instruments stands out as a leading air header manufacturer known for delivering exceptional quality and performance. Their air headers are designed with advanced technology and stringent quality controls to ensure reliability and durability in demanding environments.

McNeil Instruments’ commitment to excellence extends beyond just manufacturing. As a renowned air header supplier and air header exporter, they offer comprehensive support and service, ensuring that your system is tailored to meet the specific needs of your plant. Their products are engineered to provide consistent and reliable air supply, essential for maintaining the efficiency and safety of petrochemical processes. By deciding McNeil Instruments, you benefit from their extensive experience, high-quality products, and unparalleled customer support, making them a top choice for your instrument air header needs.

Instrument air headers are a fundamental component of petrochemical plants, ensuring that compressed air is delivered reliably and efficiently to essential instruments and control systems. Reliable air header manufacturers and experienced air header suppliers play a crucial role in providing high-quality air headers that enhance plant operations. By choosing McNeil Instruments, a leading air header exporter, you ensure that your plant benefits from top-tier equipment and comprehensive support. Understanding their components, functions, and maintenance practices is vital for maintaining the efficiency and safety of plant operations. By following best practices and leveraging the expertise of McNeil Instruments, you can optimize your air header system and ensure it meets the highest standards of quality and reliability.