Ghana’s expanding industrial, manufacturing, energy, and infrastructure sectors increasingly rely on durable, high-performance piping solutions. Among these, stainless steel tube fittings are essential components that ensure leak-free connections, corrosion resistance, and long service life in systems carrying fluids, gases, and chemicals.

This comprehensive blog explains the most commonly used stainless steel tube fittings — Grades 304, 304L, 316, 316L, 321 & 347 — their properties, applications, and relevance to Ghana’s engineering and industrial needs.

What Are Stainless Steel Tube Fittings?

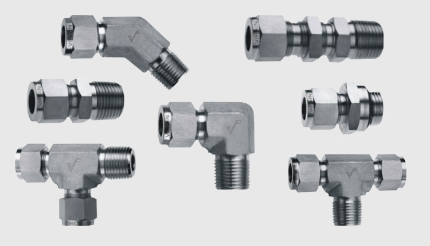

Stainless steel tube fittings are connectors used to join, redirect, or terminate tubing in various piping assemblies. They include:

● Elbows

● Tees

● Reducers

● Couplings

● Caps

● Adapters

These fittings must withstand pressure, resist corrosion, and maintain integrity across fluid systems — especially in harsh industrial conditions. Stainless steel’s superior resistance to rust, pitting, and chemical attack makes it a top choice for Ghana’s piping infrastructure.

Why Choose Stainless Steel Fittings in Ghana?

Ghana’s coastal, humid, and industrial environments expose piping to moisture and corrosive agents. Stainless steel resists:

● Salt spray corrosion

● Chemical attack

● Microbial corrosion

This makes it ideal for marine, refinery, chemical, and food processing environments.

These fittings sustain performance under:

● High pressure

● Thermal cycling

● Vibration and mechanical load

Stainless steel’s non-porous surface is perfect for:

● Food and beverage processing

● Pharmaceutical utilities

● Water treatment systems

Overview of Stainless Steel Tube Fitting Grades

Below is a detailed look at the six major stainless grades used in tube fittings supplied to Ghana:

1. Stainless Steel 304 Tube Fittings

Grade 304 is one of the most widely used austenitic stainless steels. It contains:

● 18% Chromium (Cr)

● 8% Nickel (Ni)

● Excellent corrosion resistance

● Good weldability and formability

● Strong performance in most general environments

● Food and beverage processing equipment

● General industrial piping

● Water lines and municipal utilities

● HVAC systems

2. Stainless Steel 304L Tube Fittings

Grade 304L is the low-carbon version of 304. Lower carbon minimizes carbide precipitation during welding.

● Enhanced weldability

● Lower risk of intergranular corrosion

● Ideal for fabrication-intensive applications

● Welding-intensive industries

● Chemical handling systems

● Infrastructure where post-weld corrosion resistance is crucial

3. Stainless Steel 316 Tube Fittings

Grade 316 includes molybdenum (Mo), improving corrosion resistance.

● Better resistance to chloride environments

● Higher overall corrosion resistance than 304

● Suitable where chemical exposure is heavy

● Coastal infrastructure

● Marine piping systems

● Chemical and petrochemical plants

4. Stainless Steel 316L Tube Fittings

316L is the low-carbon counterpart of 316, offering better post-weld performance.

● Excellent weldability

● Reduced carbide precipitation

● Strong corrosion resistance after welding

● Welding-critical industrial piping

● Offshore and marine construction

● Water desalination and treatment systems

5. Stainless Steel 321 Tube Fittings

Grade 321 is a titanium-stabilized austenitic stainless steel. It resists sensitization (grain boundary corrosion) at elevated temperatures.

● Good heat resistance

● Stable mechanical properties at high temperature

● Ideal where thermal cycling is common

● Heat exchangers

● Boiler feed lines

● Thermal process piping in manufacturing

6. Stainless Steel 347 Tube Fittings

Grade 347 uses niobium (Nb) stabilization, providing similar benefits to 321 but with higher creep resistance.

● Excellent stability in high-temperature environments

● Less susceptibility to intergranular corrosion

● Good mechanical strength at elevated temperatures

● Power plant piping

● High-temperature chemical processing

● Steam distribution systems

Comparative Benefits of These Grades

| Grade | Corrosion Resistance | Weldability | High Temp Capabilities | Best Overall Use |

| 304 | Good | Good | Moderate | General industrial use |

| 304L | Better after welding | Excellent | Moderate | Fabricated systems |

| 316 | Very Good | Good | Moderate-High | Marine/chemical |

| 316L | Excellent after weld | Excellent | Moderate-High | Offshore/chemical |

| 321 | Good | Good | High | Heat/thermal service |

| 347 | Good | Good | Very High | High-temperature / steam |

Stainless steel tube fittings are widely used across:

● Pipeline systems

● Control instrumentation

● Offshore drilling platforms

● Cooling systems

● Steam and feedwater piping

● Thermal plant infrastructure

● Hygienic fluid transport

● Brewery, dairy, and edible oils

● Acid and alkaline fluid lines

● Corrosive service applications

5. Water Treatment & Distribution

● Municipal systems

● Industrial wastewater handling

Why Choose Stainless Steel Tube Fittings for Ghana Projects

Corrosion Protection in Coastal Regions

Ghana’s coastal humidity and salt exposure accelerate corrosion in mild steel systems. Stainless steel avoids premature failure.

Stainless steel reduces downtime and maintenance costs — a major advantage in industrial operations.

For potable water and food processing, stainless steel meets sanitary and regulatory standards without compromising strength.

High-Temperature & Pressure Resilience

Grades like 321 and 347 handle thermal load and repeated temperature cycling with stable mechanical performance.

Choosing the Right Fitting Grade in Ghana

| Industry / Environment | Recommended Stainless Grade |

| General Industrial | 304 |

| Fabrication & Welding-Intensive | 304L, 316L |

| Marine & Coastal | 316, 316L |

| High Temp / Thermal Cycling | 321, 347 |

| Chemical Processing | 316 / 316L |

Choose based on environmental corrosion factors, thermal exposure, and fabrication needs.

Stainless steel tube fittings in Grades 304, 304L, 316, 316L, 321 & 347 provide Ghana’s industrial infrastructure with reliable performance, superior corrosion resistance, and long-term durability. Whether used in oil & gas, power plants, chemical processing, food production, or water treatment systems, these fittings ensure secure and long-lasting piping systems.

Investing in the right stainless steel tube fittings grade not only improves operational efficiency but also enhances safety, longevity, and cost savings over the life of the project.