Best Block Bleed Valve Manufacturers in India

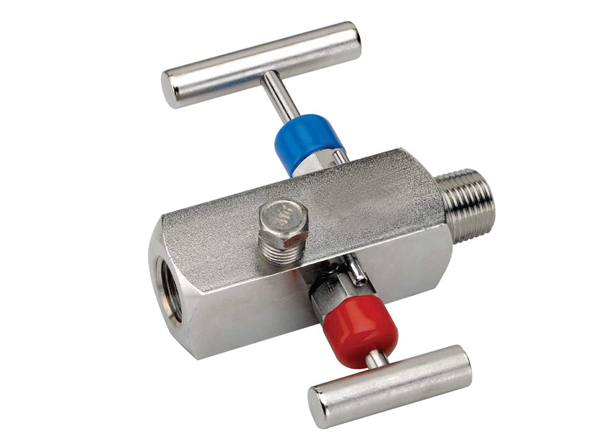

SINGLE BLOCK VALVE-MB1 SERIES

Single block and bleed valves Manufacturers, Suppliers, Exporters in India

Single block and bleed valves Manufacturers, Suppliers, Exporters in India

Single block and bleed valves are used to achieve positive isolation when performing maintenance activities in a live process plant. Typically one block valve and a bleed valve are manufactured as a single assembly and this single block and bleed valve manifold can be readily installed for isolation purpose.

There is a lot of misunderstanding surrounding the term ingle Block Valve-MB1 Series as used to describe valve functionality. It seems almost every valve buyer and manufacturer has a different idea of what the term means for valve selection, which can result in the wrong specifications or valve type. Some of this confusion in the oil and gas industry stems from the fact that there are two credible sources that define the term differently.

Single block and bleed valves are usually used for non-critical process service, such as low pressure system or non toxic, non hydrocarbon, non-hazardous process fluids. For critical service, double block and bleed valve assemblies must be used. To perform positive isolation while performing maintenance, repair or shutdown activities, single block and bleed can be used in the following way. The block valve is closed first. The shutdown side of the block and bleed assembly is then drained/vented/purged to make ready for maintenance.

Features of Mcneil Instruments Block and Bleed Valves

Live Loaded Gland Packing

Our valves are equipped with graphite packing as a standard feature to ensure fire-safe design conditions. Belleville spring washers are utilized for live loading, preventing gland loosening under vibrations and shock conditions.

Antistatic Device

To guarantee electrical continuity between the stem, ball, and body, all our floating ball valves are equipped with an integral antistatic device.

Blow Out Proof Stem

The stem is designed with a collar to provide blow-out protection, ensuring safety and reliability in operation.

Double ‘D’ Stem to Lever Connection

Our valve stems feature a Double ‘D’ connection at the top for lever fixing, which eliminates the possibility of incorrect lever assembly and ensures that the lever indicates the valve position once installed.

Equalized Cavity Pressure

A pressure equalization hole at the top of the ball, combined with a specially engineered seat design, maintains pressure balance in the line and body cavity regardless of the valve position.

Locking Device

All our valves are equipped with locking devices, suitable for both lever and gear operators, enhancing security and operational safety.

Flanged Inlet Connections

We offer ANSI B16.5 flanged inlet connections ranging from 1/2″ to 20″ sizes, accommodating a variety of installation requirements.

Pressure Ratings

Our valves are available in pressure ratings from Class 150 to Class 2500, ensuring suitability for diverse applications.

Standard Outlet and Vent

Standard outlet connections range from 1/2″-14 to 1″-11.5 NPT (female), depending on bore size. A 1/2″ NPT (female) vent is also provided as standard.

If you are searching for block and bleed valves manufacturers, suppliers, and exporters in India do contact Mcneil Instruments

Materials of Construction Use for Block and Bleed Valves

- Standard Materials: Stainless steel ASTM A182 F316/F316L, WCB & CF8M, Carbon steel ASTM A350 LF2/A105, Duplex ASTM A182 F51.

- Optional Materials: Available on request, including Stainless steel ASTM A182 F316/F316L, Carbon steel ASTM A350 LF2/A105, and Duplex ASTM A182 F51.

Flange Face Styles

Raised face and ring-type joint flange face styles are available, ensuring compatibility with various piping systems.

Construction and Design Standards of Block and Bleed Valves

- One-Piece Forged Construction: Flanges are standard.

- Fire Safe Design: Tested to meet BS 6755 Part 2/API 607 standards.

- Handles and Trim: Made of 304 stainless steel to reduce corrosion risk.

Compliance and Traceability

- Designed to meet ASME/ANSI B16.34/B16.5 pressure and temperature requirements.

- Pressure boundary designs are calculated to ASME VIII Div 1 and verified by testing.

- Materials are heat code traceable to EN 10204.3.1 standards.

Additional Features of Block and Bleed Valves

- Bubble Tight Shut Off: Ensures no leakage.

- Locking and Anti-Tamper Devices: Available for all valve types.

- Positive Lever Stop: Ensures precise operation.

- User-Preferred Handles: For ease of use.

- Permanent Affixed Reference Label: For easy identification and maintenance tracking.

Mcneil Instruments block and bleed valves are engineered to provide reliable, safe, and efficient operation in various industrial applications.

Material use for Manufacturing Block Bleed Valve

Part Name | Casting | Forgings |

VALVE BODY | A 216 WCB, A 351 CF8 | A 105, A 350 LF2 , A 350 LF3, A 182 F6a |

STEM | A 105, A 350 LF2 , A 350 LF3, A 182 F6a | |

SOFT SEAT | PTFE , RPTFE, NYLON 12-G, DEVLON , PEEK | |

SEALS | NITRIL, EPDM, VITON B, VITON GLT | |

GASKET | PTFE, RPTFE, GRAPHITE | |

STUDS/BOLTS & NUTS | A 193 GR. B7 A 193 GR. B7M A 320 L7 A 320 L7M A 320 L43 A 193 GR. B8 A 193 GR. B8M A 194 GR. 2H A 194 GR. 2HM A 194 GR. 7 or GR.4 A 194 GR 7M A 194 GR. 7M A 194 GR. 8 A 194 GR. 8M | |

Specification of Block Bleed Valve

| Specification | Details |

|---|---|

| Material Options | – Stainless Steel (304, 316, 316L) – Carbon Steel – Alloy Steel – Nickel Alloys – Brass – Monel |

| Size Range | – Typically ranges from 1/2 inch to 6 inches in diameter – Custom sizes available |

| Pressure Rating | – Up to 6000 PSI (depending on the material and size) |

| Temperature Range | – Typically -20°C to 400°C – High-temperature options available |

| End Connections | – Threaded (NPT, BSPT) – Flanged (ANSI, DIN) – Welded |

| Type of Valve | – Single Block and Bleed Ball Valve – Block and Bleed Valve |

| Sealing Type | – Soft Seat (e.g., PTFE, Viton) – Metal Seat (e.g., Stainless Steel, Inconel) |

| Flow Configuration | – Full Port – Reduced Port |

| Surface Finish | – Electropolished – Shot Blasted – Pickled and Passivated |

| Standards and Certifications | – API (American Petroleum Institute) – ANSI (American National Standards Institute) – ISO (International Organization for Standardization) – BS (British Standards) |

| Testing and Quality Control | – Hydrostatic Testing – Functional Testing – Non-Destructive Testing (NDT) – Chemical and Mechanical Analysis |

| Body and Trim Material Options | – Carbon Steel (ASTM A216 WCB) – Stainless Steel (ASTM A351 CF8M) – Alloy Steel (ASTM A217 WC6) |

| Operation Type | – Manual (Handwheel or Lever) – Actuated (Pneumatic or Electric) |

| Leakage Class | – Class IV (for soft-seated valves) – Class VI (for metal-seated valves) |

| Application Areas | – Oil and Gas – Petrochemical – Power Generation – Chemical Processing – Water Treatment |

Technical Specifications of Block Bleed Valve

Bore sizes | As per API 6D. |

Seat materials | TFM, PEEK, Metal |

Body materials | 316 Stainless Steel ASTM A182-F316/ UNS S31600 Duplex ASTM A182-F51 / UNS S31803 Super Duplex ASTM A182-F53/F55 Low Temp Carbon Steel ASTM A350 LF2 Alloy 625 UNS N06625 Alloy 825 UNS N08825 |

Valve configurations | Flange x screw |

Max. Working Temperature | 360o C |

Min. Working Temperature | -196o C |

Max. Working Pressure | Pressure 6,250 PSI (431 bar) |

For reliable and high-quality block bleed valves, look no further than Mcneil Instrument. As leading Block Bleed Valve Manufacturers, Block Bleed Valve Suppliers, and Block Bleed Valve Exporters, Mcneil Instrument offers a comprehensive range of products designed to meet the stringent requirements of various industries. Our block bleed valves, including the single block and bleed ball valve, are crafted with precision engineering and adhere to international standards, ensuring optimal performance and durability in critical applications. Whether you need block bleed valves for oil and gas, petrochemical, or other industrial processes, Mcneil Instrument, one of the top block valve suppliers, has you covered. With a commitment to excellence and customer satisfaction, we strive to deliver superior products and unmatched service to our clients worldwide. Contact us today to explore our range of block bleed valves and experience the Mcneil Instrument difference.

Products

- It is a combination of needle & manifold valves thus redusing the number of joints.

- Spindle : ground and thread rolled.stem tip 17-4ph for long life.

- Dust cap protects stem threads from external contamination leak tight seal with low operating torque heat code traceability ball hard chrome plated for smooth opertions.

- Hydrostatic shell test is performed at 1.5 times the working pressure.

- Standard Test : each valves is tested with nitrogen at 1,000 psi for seat & packing leakage, with a max. Allowable leak rate of 0 .1 std. Cm3 / min.

- Optional test are available upon request

Molybdenum disulphide (mos2)

SIZE | A | B | CSQ | WEIGHT (kg) |

1/4″ | 93 | 55 | 25 | 0.36 |

3/8″ | 93 | 55 | 25 | 0.37 |

1/2″ | 95 | 66 | 28 | 0.46 |

3/4″ | 109 | 70 | 38 | 0.8 |

1″ | 117 | 80 | 45 | 1.3 |

Monel :

Grade: Monel 400, Monel K500, Monel R-405

Nickel :

Grade: Nickel 200, Nickel 201

Inconel :

Grade: Inconel 600, Inconel 601, Inconel 625, Inconel 718

Incoloy :

Grade: Incoloy 800, Inconel 800H, 800HT

Hastalloy :

Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X

Titanium :

Grade: Gr1, Gr2, Gr3, Gr5, Gr7, Gr11

Stainless Steel :

Grade: ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 304H, 316H, 316/316L, 321, 330, 347, 309/S, 310/S, 317/L, 333, 410/S, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel :

Grade: ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70, SA105

Duplex Steel:

Grade: ASTM / ASME A/SA 182 UNS F44, F45, F51, F53, F55, F60, F61

Alloy Steel:

Grade : ASTM SA 182 – E25, E26, E27, E28, E29B, E30B, E39B, E40B, E36B, E36C, E41B, AISI4130, AISI4140, AISI4340, 42CRMO4, 16MNCR5, 20MNCR5, 21CrMoV57, EN353, EN354, F11, F22, F91, F9, P11, P22, P91, P9, P5, P92, EN42J, EN8, EN19