IBR Approved Tubes Manufacturer, Supplier & Exporter – Mcneil Instruments

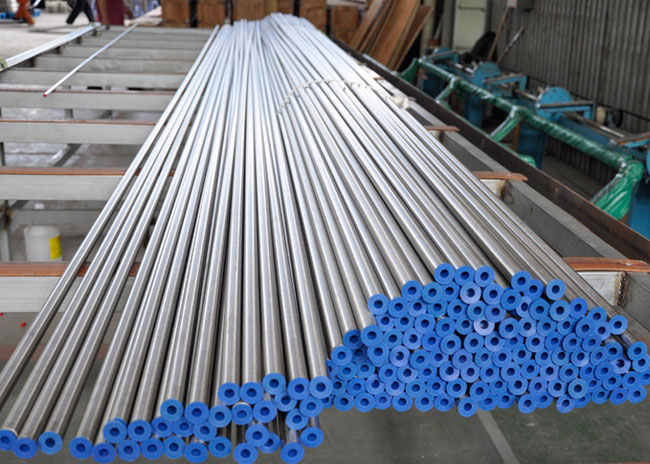

Mcneil Instruments is a trusted manufacturer, supplier, and exporter of IBR-approved tubes, catering to industries that require high-quality, regulation-compliant boiler tubes for critical applications

What are IBR Approved Tubes?

IBR (Indian Boiler Regulations) approved tubes are designed to meet stringent safety and performance standards set by the Indian government. These tubes are primarily used in boilers, power plants, oil & gas refineries, and chemical industries to withstand high pressure and temperature conditions.

Key Features:

✔ Made from carbon steel, alloy steel, and stainless steel

✔ Available in multiple grades like ASTM A106 Gr B, ASTM A335 P5, P9, P11, P22, P91

✔ Rigorous testing – hydrostatic, ultrasonic, eddy current & non-destructive testing

✔ Available in various sizes, thicknesses & schedules to match industrial requirements

Types of IBR Approved Tubes

IBR Approved Alloy Steel Tube

IBR Approved Hastelloy Tube

IBR Approved Inconel Tube

IBR Approved Stainless Steel Tube

IBR Approved Stainless Steel Seamless Tube

IBR Approved Copper Tube

IBR Approved 310 Stainless Steel Tubing

IBR Approved 317L Stainless Steel Tubing

IBR Approved 904L Stainless Steel Tubing

IBR Approved ASME SA 213 TP 304 Stainless Steel Tube

IBR Approved ASME SA 213 TP 304L Stainless Steel Tubing

IBR Approved ASME SA 249 TP 304 Welded Stainless Steel Tube

IBR Approved ASME SA 268 TP 410 Stainless Steel Tubing

IBR Approved ASME SA213 TP 316L Stainless Steel Tube

IBR Approved ASME SA213 TP 321 Stainless Steel Tubing

IBR Approved ASME SA213 TP 316 Stainless Steel Tube

IBR Approved ASTM A511 Stainless Steel Seamless Tubing

IBR Approved ASTM A213 TP 347 Stainless Steel Seamless Tubing

IBR Approved ASTM A213 Stainless Steel 316ti Seamless Tube

IBR Approved ASTM A270 Sanitary Tubing

IBR Approved ASTM A554 Stainless Steel Square Tube

IBR Approved ASTM A269 Stainless Steel Tube

IBR Approved Stainless Steel Boiler Tube

IBR Approved Stainless Steel Capillary Tube

IBR Approved Stainless Steel Condenser Tubes

IBR Approved Stainless Steel Cold Drawn Tube

IBR Approved Stainless Steel Coil Tubing

IBR Approved Stainless Steel Heat Exchanger Tube

IBR Approved Stainless Steel Corrugated Tube

IBR Approved Stainless Steel Instrumentation Tubing

IBR Approved Stainless Steel Rectangular Tubing

IBR Approved Stainless Steel Heat Exchanger Tube

IBR Approved Tube Specifications:

| Category | Specifications |

| Material Grades | Stainless Steel: TP 304, 304L, 316, 316L, 321, 347, 310, 904L Carbon Steel: ASTM A106 Gr B, API 5L Gr. B, X42, X52, ASTM A53, ASTM A179, ASTM A192 Alloy Steel: ASTM A335 P1, P5, P9, P11, P12, P22, P91, ASTM A213 T1, T5, T9, T11, T12, T22, T91 Low-Temperature Carbon Steel (LTCS): ASTM A333 Gr. 3, Gr. 6 |

| Size Range | Outside Diameter (OD): 21.3mm – 660mm (1/2” – 26”) Wall Thickness (WT): 4.5mm to 60mm Length: Single Random (SRL), Double Random (DRL), Custom Lengths |

| Schedules | SCH 5, SCH 10, SCH 40, SCH 80, SCH 160, SCH XXS |

| Surface Finish & Coating | Galvanized, Black Coated, 3LPE Coating, FBE Coating, Epoxy Coating Rust Prevention Treatment Available |

| End Finish | Beveled End (BE), Plain End (PE), Threaded End (TE) |

| Testing & Certification | Non-Destructive Testing (NDT), Hydrostatic Test, PMI, Radiography, Ultrasonic Testing IBR Certification, ISO 9001, EN 10204:3.1/3.2, NACE Compliance |

Applications:

IBR approved tubes are widely used in various industries and applications, including:

- Boiler Manufacturing: For constructing boiler tubes, superheaters, and economizers.

- Power Plants: In steam generation systems and heat exchangers.

- Refineries and Petrochemical Plants: For high-pressure piping and process equipment.

- Sugar Mills: In evaporators and other process equipment.

- Fertilizer Plants: For ammonia synthesis and other high-pressure applications.

Why Choose IBR Approved Tubes?

- Safety Assurance: IBR approval provides peace of mind, knowing that the tubes meet the highest safety standards.

- Legal Compliance: Using IBR approved tubes ensures compliance with Indian Boiler Regulations, avoiding legal issues and penalties.

- Reliability and Performance: These tubes are designed to deliver reliable performance in demanding environments.

- Quality Guarantee: IBR approval signifies a commitment to quality and excellence.

- Industry Recognition: IBR approved tubes are recognized and trusted by industries across India.

Selecting the Right IBR Approved Tubes:

When selecting IBR approved tubes, consider the following factors:

- Material Grade: Choose the appropriate material grade based on the application and operating conditions.

- Dimensional Specifications: Ensure the tubes meet the required dimensions and tolerances.

- Pressure and Temperature Ratings: Select tubes that can withstand the operating pressures and temperatures.

- Manufacturer’s Reputation: Choose a reputable manufacturer with a proven track record of quality and reliability.

- Certification and Documentation: Verify the IBR approval and ensure that the tubes come with complete material test certificates.